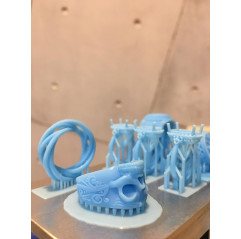

Formfutura Dental LCD Model Resin is a high-precision photopolymer resin designed for accurate modelling of dental models, aligner models, gums, teeth, crown and bridge models with removable dies. Dental LCD Model is specifically engineered to work with all open source LCD and DLP 3D printers in the range of 385 - 420nm.

Dental LCD Model resin has a surface finish and color similar to gypsum, which perfectly accentuates depth and detail in the dental model. Formfutura Dental LCD Model resin is meant for modelling purposes only and not for intraoral use.

Key features

High-resolution 3D printing with fine detail

Almost Odorless processing

Excellent dimensional accuracy and low shrinkage

Gypsum-like texture and color

Temperature resistant for dental aligner production

Compatible with all open source LCD and DLP 3D printers in the range of 385 - 420nm

Applications

Models of dentures

Implant models

Crown and bridge models

Models of gums

Orthodontic models

Resin properties (uncured liquid)

Viscosity: 700 cps at 25°C

Density: 1.18 g/cm2

Mechanical properties

Test method on post cured objects through 30 minutes high power LED curing.

Properties Typical Value Test Method

Glass transition temperature (Tg) 61°C ASTM D7028

Water absorption 0.4% ASTM D570-98

Impact strength (IZOD notched) 17 J/m ASTM D256A

Tensile strength 46 MPa ASTM D638M

Tensile Modulus 1100 MPa ASTM D638M

Elongation at break 8% ASTM D638M

Flexural Strength 68 MPa ASTM D790M

Flexural Modulus 1900 MPa ASTM D2240

Shore D Hardness 83 ASTM D2240

Please note that the above-displayed values can vary with individual machine processing, post-curing parts, geometry, print orientation, print settings, and temperature.

Preparation(s) before starting to print

Shake the bottle for at least 2 minutes before each use.

After shaking the bottle, leave the resin to rest for 10 minutes to let air bubbles get out of the resin

The resin can be poured back from the vat into the bottle once your print is finished

Always use protective measurements like safety glasses and nitrile gloves when handling resins.

General printing guidelines

Burn-in layers: 2x 170 sec

Base layer curing times at 50 microns: ±14 - 17 sec

Post-processing

We do advise you to post-process your 3D print in order to achieve the material properties

Rinse your 3D printed object in IPA or (Bio)Ethanol for approximately 5 minutes

An ultrasonic cleaner is preferred/recommended

Make sure that IPA and/or (Bio)Ethanol rinsed objects are perfectly dry before further post-curing

Place the rinsed parts in a well-ventilated area for at least 30 minutes, or use pressurized air for at least 2 minutes

Cure your object in a high power curing chamber for approximately 20-30 minutes at 65° C

The preferred curing wavelength is between 300-410nm

Safety

Please always be aware that when 3D printing with resins that you are working with chemicals and that you should always be cautious and use the personal protective equipment as stipulated in our safety data sheets.

Always wear Respiratory Protection when sanding/cutting the resin object.

Always use nitrile gloves when handling resins and uncured resin objects.