Worldwide express shipping

Worldwide express shipping

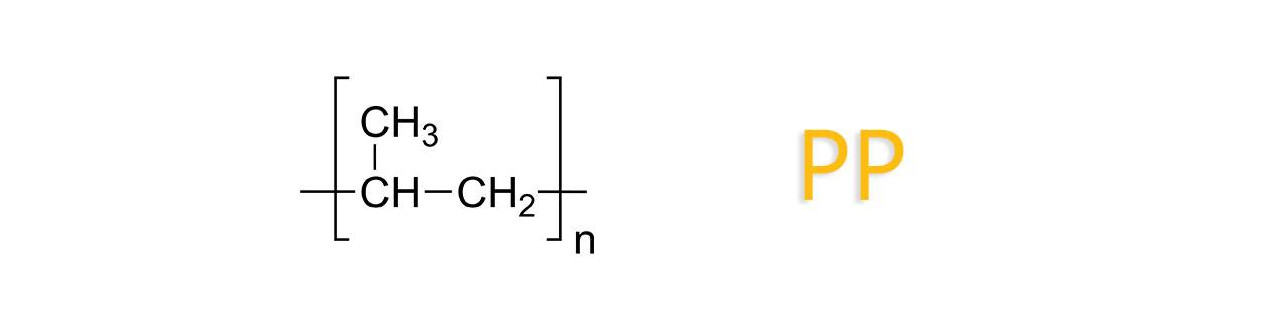

PP - Polypropylene

Polypropylene filament (PP)

PP filament: polypropylene thread for FDM printers. PP thread compatible with food contact.

PP (Polypropylene) is a recently added filament to the range of materials printable with FDM machines. Polypropylene (PP) filament is a thermoplastic polymer and is one of the most commonly used plastics in the world. It is a semi-rigid and lightweight material commonly used in storage and packaging applications.

Characteristics of the polypropylene filament

The PP thread is extremely abrasion resistant, it also offers greater thermal, chemical and electrical resistance than ABS and PLA. In addition to the excellent mechanical properties of stiffness, tensile strength, it also has resistance to chemicals such as acids, alkalis and organic solvents. PP is a material of choice for prototyping, mechanical applications and functional parts. The print result is similar to a nylon printed object, plus it does not absorb water.

Its light weight and excellent strength / weight ratio are an important asset. Finally, the polypropylene filament allows for the 3D printing of semi-flexible parts with a good surface finish (smooth and relatively soft to the touch). The printed parts are durable and resistant to high temperatures (up to 100°C), humidity and UV rays.

Possible applications of polypropylene

PP filaments are often used in the automotive, medical, and packaging industries. In the engineering world, polypropylene filament allows you to print strong and durable zippers or connectors. PP is often used as the final material. Due to their low density, polypropylene filaments make it possible to produce lightweight parts. Their excellent bonding between the layers allows for the 3D printing of flexible and waterproof objects such as molds. The objects printed in PP are also compatible with contact with food: the filaments are guaranteed without Bisphenol A (BPA).

Polypropylene filament printing

PP is relatively difficult to work with compared to a normal filament, as it tends to warp and has poor adhesion. 3D printing with polypropylene filament therefore requires a 3D printer with a heated bed. The presence of a hot chamber would also be ideal, so as to ensure a constant temperature and avoid sudden cooling of the wire after extrusion. A polypropylene surface can be used as a printing base to ensure optimal adhesion to the surface.

There are 7 products.