Introduction

In the world of 3D printing, achieving high-quality results is closely related to understanding and applying the concepts of accuracy, precision, and tolerance.

These terms, although often confused, have distinct meanings that significantly affect the final product.

In this technical article, we will explore these concepts in detail and discuss how to apply them to optimize your 3D prints.

Definitions: Accuracy, Precision and Tolerance

Accuracy

Accuracy represents how close a measurement is to the actual or ideal value.

In terms of 3D printing, accuracy refers to how closely a print accurately reflects the dimensions designed into the model CAD. High accuracy means that the print is very close to the original specifications.

For example, if the design calls for a 10 mm diameter hole, an accurate printer will create a hole very close to this size.

Accuracy

Accuracy measures the repeatability of measurements, that is, the consistency of results.

In 3D printing, accuracy translates into the printer's ability to produce identical results in successive prints. Even if the prints are not accurate to the model CAD, an accurate printer will always produce the same deviations.

For example, if a printer produces a 9.8 mm hole instead of 10 mm every time, it is accurate but not precise.

Tolerance

Tolerance is the user-defined range of acceptable error.

In the context of 3D printing, tolerance determines how far a print can deviate from the ideal value without compromising the functionality or aesthetics of the part.

For example, a tolerance of ±0.2 mm may be acceptable for a toy, but not for a mechanical component that must fit perfectly with other parts.

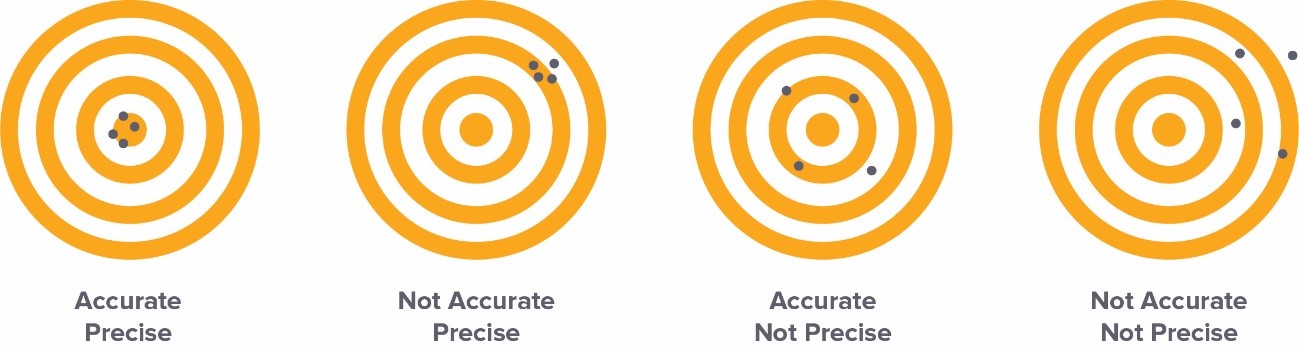

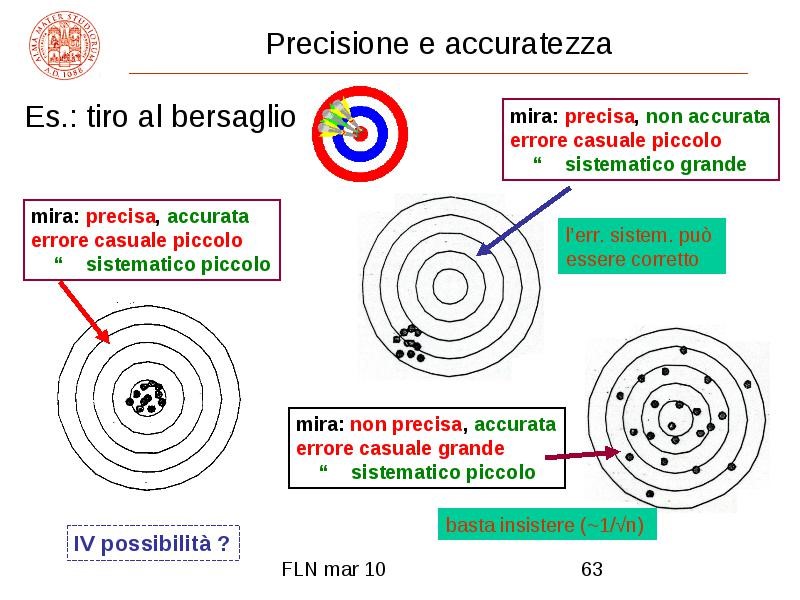

Figure: Accuracy, Precision and Tolerance

Target Analogy to Explain Accuracy and Precision.

The target analogy helps to better visualize these concepts:

- Accurate and Precise: Measurements are close to the true value and each other.

Imagine a target with all shots close to the center.

- Accurate but not accurate: The measurements are close to each other but far from the true value.

The shots are grouped together but far from the center of the target.

- Accurate but not precise: Measurements are close to the true value but not repeatable.

Shots are close to the center but scattered.

- Neither accurate nor precise: Measurements are far from the true value and variable from each other.

Shots are scattered and far from the center of the target.

Figure: Analogy of the Target to Explain Accuracy and Precision.

Application in 3D Printing

Accuracy in 3D Printing

To ensure high accuracy in 3D printing, it is essential to calibrate the printer correctly, making sure that the axes, extruder, and print bed are aligned precisely.

Material selection is crucial; prefer those with low dimensional changes during cooling to avoid deformation.

Also, optimizing printing parameters, such as temperature, speed, and layer height, helps reduce discrepancies between designed and final dimensions.

Accurate calibration and the use of appropriate materials improve the accuracy of your prints, ensuring that the final products reflect the model specifications CAD.

Accuracy in 3D Printing

To improve accuracy in 3D printing, it is critical to maintain a constant printbed temperature to avoid deformation.

A rigid, well-assembled printer structure reduces vibration, ensuring consistency between successive prints.

Performing regular maintenance is equally important: replace worn components and lubricate axes to maintain machine precision.

A well-maintained and stable printer can produce consistent and repeatable results, which are essential for projects that require high precision.

Tolerance in 3D Printing

Managing tolerances in 3D printing is critical to tailor prints to specific project requirements.

Clearly define acceptable tolerances based on the end use of the part; for example, mechanical components may require tighter tolerances than aesthetic models.

Choose materials and printing techniques that meet these tolerances, such as laser sintering for more precise results.

Also consider using post-processing techniques, such as CNC machining or sanding, to further refine tolerances and improve the final quality of the part.

Summary:

- Accuracy: Printer calibration, choice of materials with low dimensional variations, optimization of printing parameters.

- Accuracy: Print bed temperature stability, rigid machine design, regular maintenance.

- Tolerance: Definition of acceptable tolerances, choice of appropriate materials and processes, use of post-processing techniques to refine tolerances.

Conclusion

Understanding and applying the concepts of accuracy, precision and tolerance is essential to take full advantage of the capabilities of 3D printing.

These concepts allow the quality of prints to be optimized, ensuring that they meet the specific requirements of the project.

With a good understanding of these terms, 3D printing results can be significantly improved, resulting in more reliable, high-quality end products.

©Compass DHM projects