E3D is a company that specializes in manufacturing 3D printer components, including high-quality hotend. Thehotend is an essential part of the 3D printer that fuses and deposits the printing material layer by layer.

Bambu Lab, on the other hand, has been named, thanks to its X1 printer, one of the best inventions of 2022 by TIME. A young company that has exploded in the past year, it continues to amaze and launch innovations in the world of 3D printing. Bringing about a revolution in thinking about filament 3D printing, bringing it closer to an even wider audience.

The History of E3D and the Innovation of Bambu Lab.

The inspiration for E3D's new HotEnd came from the fact that Bambu Lab printers have a high speed of movement.

This, however, we know does not keep up with print speed, which is often limited by various factors. One of these is the flow of molten material intohotend.

Through its experience with Revo High Flow, E3D undertook extensive research on the internal geometry of nozzle, providing the impetus to improve the perofrmance of the Bambu Lab X1 printer.

Thus a new HotEnd was born, taking advantage of E3D's High Flow geometry, which showed outstanding performance during testing.

Bambu Lab: The Improved Performance

This HotEnd developed by E3D enabled an increase in material flow of more than 60 percent compared to the standard, leading to a significant increase in the productivity of the Bambu Lab X1.

This is a perfect combination between a long-standing manufacturer in the world of consumer 3D printing like E3D, and Bambu Lab, which recently won the prestigious "Consumer Printer of the Year" award at the 2023 3DPI Awards for the X1 printer.

|

|

Strategic Collaboration with Bambu

The partnership between E3D and Bambu Lab ushers in a series of strategic collaborations, paving the way for official third-party components within the Bambu Lab landscape.

Through the partnership with E3D, the expertise of both companies has been combined to develop a product that lives up to the required quality standards and user expectations.

Specifications and Key Features

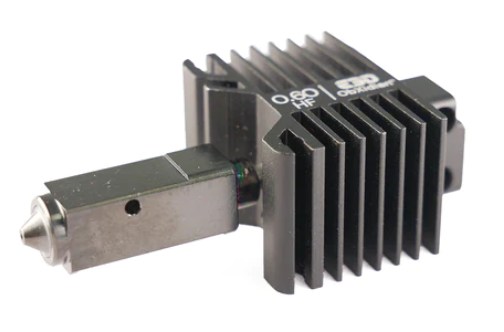

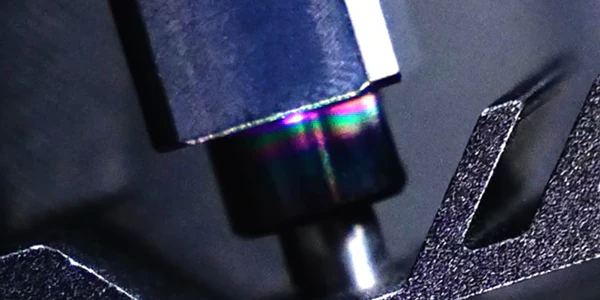

E3D's new Obxidian HotEnd for BambuLab features a High-Flow insert made of hardened steel, a copper heating block, and an ObXidian coating to improve performance in every aspect.

The E3DLC™ coating reduces plastic buildup and also provides greater wear resistance.

Upgrading to the E3D ObXidian HF Bambu Hotend is rapido and requires no changes to firmware or structure. Using Bambu's standard documentation, the upgrade takes less than 10 minutes. HotEnds are available with 0.4 mm and 0.6 mm nozzles, which are easily identified by the clear engraving on the heat sinks provided by Bambu.

Innovation and the Future

With the design approved by Bambu, production is already underway, combining the supply of the HeatSinks by BambuLab with the fabrication and assembly of the nozzles and inserts by E3D in Oxfordshire.

This new HotEnd promises to revolutionize the 3D printing experience once again, bringing significant improvements on already high-performing products.

The main questions for this new hotend from E3D are.

What are the usable filament sizes?

Filament diameter: 1.75 mm

What BambuLab printers is the new hotend E3D Obxidian High Flow compatible with?

This new hotend is compatible with the following Bambu Lab printers: X1, X1 Carbon, X1E, P1S and P1P.

What is the maximum printing temperature?

E3D'shotend Obxidian Higl Flow for Bambu Lab can reach a printing temperature of 300°C.

Is it possible to cold-press thehot end E3D ObX HF Bambu?

Yes, it is possible! The ObXidian coating is designed to withstand the force of a cold pull, however it can be a bit challenging compared to a typical nozzle because of the internal structure.

Are there any limitations on materials?

With this upgrade you can use any filament you print with the E3D Revo and V6 ObXidian nozzles. Generally, these nozzles are intended for loaded filaments, so with carbon fiber or fiberglass, phosphorescent filaments and filaments with glitter.

You can also use it for short periods with metallic and ceramic filaments, but prolonged use could result in rapid wear.

Is it necessary to perform PID calibration when switching to the E3D ObX HF Bambu HotEnd?

No, it is not necessary!

Is it compatible with E3D nozzles Revo?

These Hotend are designed to maintain the same form factor as the stock BambuLab nozzles and are therefore not compatible with the E3D nozzle range Revo.

If you are interested in installing a Revo nozzle on a BambuLab, we suggest you take a look at the Revo Panda. Biqu Revo Panda is a hotend made by Biqu in collaboration with E3D that allows you to install a Revo nozzle , of the type you prefer, on a BambuLab printer (either X1 or P1 series): Standard Flow brass, High Flow brass, Standard Flow High-Temperature, High-Temperature Abrasive, Obxidian Standard Flow and DiamondBlack Standard Flow.

Learn about all of E3D's hotend and nozzles in the dedicated section.

Need more information?

Check the product sheet for all the technical information, or CONTACT US.

Image source: E3D - BambuLab - Biqu