PEI planes for FDM 3D printers: let's discover the planes of the DHM pro line

The printing platens in the DHM pro line are designed to achieve the best performance. Let's look at the PEI-coated platens in particular today.

PEI-coated printing platens are the result of a careful choice of raw materials. They are harmonic steel plates coated with Ultem® resin. They allow a two-layer system to be created in conjunction with the dedicated magnetic platen. They are easy to install and provide strong adhesion to many materials.

The PEI mat is a flexible plane coated with Ultem® 1000. This high-heat thermoplastic polyetherimide polymer is designed for injection molding.

With continuous use above 170°C (about 340 degrees Fahrenheit), Ultem® 1000 has exceptional flame resistance, this is a guarantee of safety on your 3D printers that can become dangerous if left unattended to work at high temperatures.

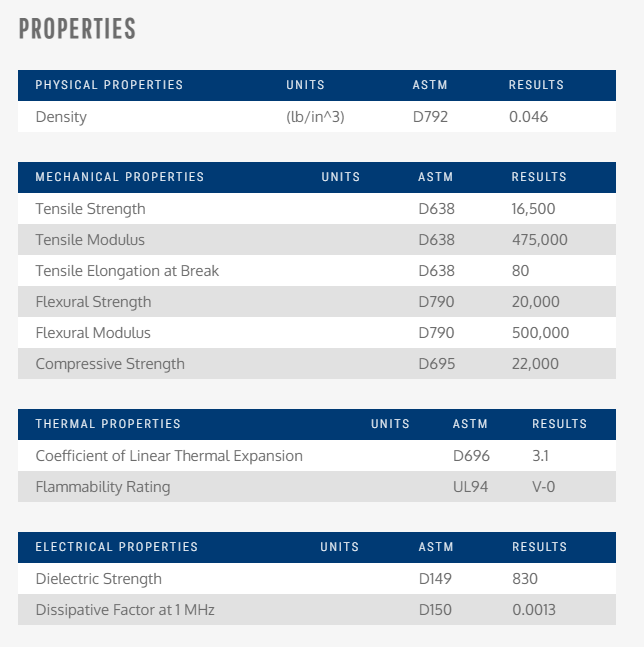

CHARACTERISTICS OF ULTEM® RESIN

Let's take a detailed look at the main characteristics of Ultem® resin used to make our PEI planes for 3D printers:

- High heat resistance

- Chemical resistance to alcohols, acids, hydrocarbons and more.

- High mechanical strength

- Flame retardant

- Rigidity and dimensional stability

- Resists stress cracking

- Glass transition temperature (Tg): 217 C°, HDT/Ae of 190°C

- Relative Thermal Index (RTI): 170°C

APPLICATIONS OF ULTEM® 1000 in 3D printing planes.

Due to its high mechanical strength and heat-resistant composition, Ultem® 1000 is ideal for use in harsh environmental conditions that require chemical and high temperature resistance characteristics.

Therefore, it is ideal in use as a print bed on filament 3D printers.

ADVANTAGES of ULTEM® RESIN for 3D printing planes.

- High dielectric strength

- High strength

- Operates in continuous use at over 170°C

- Scratch-resistant, difficult to damage even when the nozzle collides against it

- You can decide the printing side (our PEI platens are coated on both sides)

- No need to apply adhesives for PETG

- Prints come off automatically as soon as the platen cools down

The PEI-coated platen of the DHM pro line is available in various sizes and patterns:

- PEI-surfaced plate with one textured side and one smooth side

- Plate with PEI surface with both sides textured

- Plate with PEI surface with one textured side

Find out in the dedicated section if there is a size for your printer or request it via the contact form, we will be happy to help you optimize your 3D printer with top-of-the-line components.

In particular, PEI platens are available on our e-shop for all models of 3D printers Voron (Voron 2.4, Voron Trident , Voron Switchwire and Voron 0.1) in fact, the original designs Voron foresee and recommend the exclusive use of a magnetic platen with PEI coated flexible mat to be applied to the aluminum platens machined to size.

These PEI-coated printing planes are the best solution for printing PLA without the use of adhesives or glues, in fact they offer excellent adhesion with almost all materials. In addition you will get an aesthetic effect on the bottom of your prints: if you use the smooth surface it will be smooth, otherwise if the textured side is used the surface of the prints will be slightly knurled. This many times hides possible defects in the first layer, which are visible in the case of the smooth surface instead.

Here are the temperatures of use for the most commonly used materials:

- PLA: 40°c - 60°c (60°c is recommended for objects with a wide base)

- PETG: 75°C - 85°C

- ABS: 90°C - 100°C

With this configuration, removing the prints is quick and easy: just wait for the board to cool, tilt slightly, and the prints will come off on their own. Be careful, however: to ensure longer shelf life and avoid damage to the prints, remember to wait for both the shelf and the printed object to cool down to room temperature.

Maintenance of ULTEM® coated platens is also quick. After removing the flexible platen from the printer's magnetic platen and detaching the printed objects you can clean them using 90% isopropyl alcohol (IPA).

Caution.

Never use acetone to clean the rough PEI powder coated flexible steel plate! In fact, acetone creates micro-fractures in the PEI texture, which leads to deterioration of the surface over time.

Also, do not wash the PEI top with water. Wait for the platen to cool before removing it from the printer and folding it to remove the printed piece. We do not recommend using tools to remove printed pieces. For example, avoid using spatulas that can damage the coated surface of the platen.

So we have seen the main features of the DHM pro line 3D printer planes coated with PEI ULTEM.

Learn about the 3D printing planes of the DHM pro line in the dedicated section.

Need more information?

Check the product sheet for all the technical information, or CONTACT US.