Let's look at the main characteristics of ULTEM® polyetherimide resins, and explore their use in 3D printing.

Polyetherimide resins: what are they?

ULTEM® polyetherimide resin, PEI, is a high-performance amorphous polymer that is characterized by excellent thermal properties, good chemical resistance, inherent flame retardancy, and and exceptional dimensional stability.

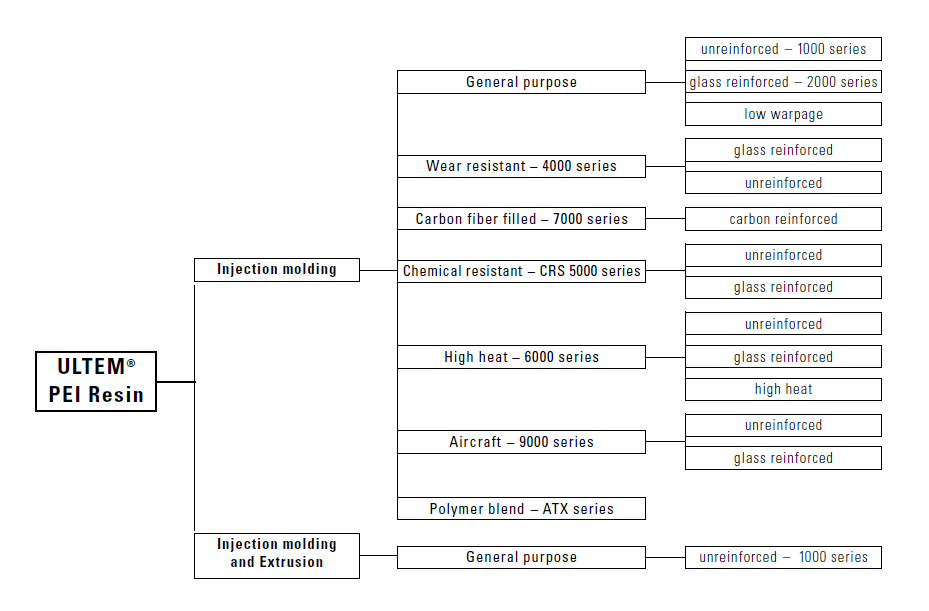

The ULTEM family includes several types of resins, which we will now look at together.

The ULTEM® Series.

In addition to the ULTEM® 1000 series, other types are also found on the market:

- ULTEM® 1000 Resins Basic polymer

- ULTEM® 2000 Resins

- ULTEM® 3000 Resins

- ULTEM® 4000 Resins

- ULTEM® CRS 5000 Resin

- ULTEM® 6000 Resins

- ULTEM® 7000 Resins

- ULTEM® 9000 Resins

- ULTEM® ATX Resins (polyetherimide/polycarbonate-ester blend)

The key properties of ULTEM® 1000 resin base.

ULTEM® 1000 resin has a few key characteristics:

- High long-term heat resistance, with a glass transition temperature (Tg) of 217°C, HDT/Ae of 190°C and relative thermal index (RTI) of 170°C

- Intrinsic flame retardancy with low smoke evolution, complying with ABD, FAR and NBS standards

- Excellent dimensional stability (low sensitivity to creep and low uniform coefficient of thermal expansion)

- Exceptional strength and modulus at elevated temperatures

- Resistance to a wide range of chemicals, such as automotive fluids

- such as automotive fluids, fully halogenated hydrocarbons, alcohols

- fully halogenated hydrocarbons, alcohols and aqueous solutions

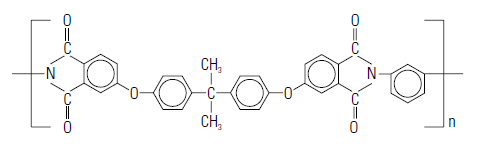

Specifically, the base polymer ULTEM® 1000 has a transparent amber-brown color, is produced by polycondensation, and has the following chemical structure:

Typical applications of ULTEM® 1000 resin

- Medical

- Aeronautics

- Automotive

- Automotive lighting

- Interconnect devices

- printed interconnect devices (MIDs)

- Electrical and lighting

- HVAC / Fluid Handling

- Tableware / Catering

ULTEM® 2000 Resins

Reinforced with glass fiber

Improved stiffness compared with ULTEM® 1000 resin

Improved dimensional stability compared with ULTEM® 1000 resin

Availability of low-viscosity grades

ULTEM® 3000 Resins

Filled with glass and minerals

High strength

Better dimensional stability than ULTEM® 2000 series

ULTEM® 4000 Resins

Wear resistance

Reduced coefficient of friction

Unreinforced and glass-reinforced types

ULTEM® CRS 5000 Series Resin

Superior chemical resistance compared to ULTEM® 1000 resin

Better resistance to hydraulic fluids used in aviation than ULTEM® 1000 resin

Unreinforced and glass-reinforced grades

ULTEM® 6000 Resins

Highest heat resistance of all ULTEM® resins

ULTEM® 7000 Resins

Reinforced with carbon fibers

Exceptional strength-to-weight ratio

Highest modulus of all ULTEM resins

ULTEM® 9000 Resins

Meets aviation industry regulations (ABD, FAR, OSU and NBS)

Delivered with individual lot certification

Unreinforced and glass-reinforced grades

Extrusion and injection molding grades

ULTEM® ATX resins (polyetherimide/polycarbonate-ester blend)

Intermediate thermal performance

ULTEM® ATX 100 resin offers higher impact performance than ULTEM® 1000 resin

Very high flow rate compared to ULTEM® 1000 resin

Metallizable without primer

Availability of grades compliant with food contact

What type of ULTEM resins are used in FDM 3D printing?

Specifically, ULTEM 1010 and ULTEM 9085 are used for 3D printing.

ULTEM 1010

ULTEM 1010 one of the strongest materials in the FDM family of thermoplastics. This grade of ULTEM has excellent mechanical and thermal strength, allowing it to be used in steam autoclaves without cracking.

ULTEM 1010 is a self-extinguishing material (V0) and withstands temperatures up to 216°C. It is also certified biocompatible (ISO 10993/USP Class VI) and suitable for food contact (NSF 51). Thanks to these special properties ULTEM 1010 is ideal for use in advanced equipment in the automotive, aerospace, medical and food industries.

ULTEM 9085

ULTEM 9085 has a lower flexural strength, making it more ductile but still strong.

It is a lightweight, high-strength and fully self-extinguishing material. Its main characteristics are: high chemical and heat resistance and excellent tensile and flexural strength.

ULTEM 9085 is specifically formulated to be flame retardant according to UL 94 VO, and it is also a certified FST (Flame, Smoke, Toxicity) material.

Prototypes made of ULTEM® 9085 are suitable for functional testing under extreme conditions, requiring high performance, resistance to chemicals and use at elevated temperatures. Thus there are applications in industries where material performance is decisive such as aerospace (FAR certificate 25.853) and aeronautics, as well as in speed and racing-related fields.

It can in some cases replace aluminum since it is a lighter material and, at the same time, extremely durable.

Whether for functional prototypes or final applications, ULTEM resin's strength and existing certifications make it a good choice for a variety of parts.

How to print ULTEM high-performance thermoplastic?

Printing ULTEM filaments requires a 3D printer that supports high-temperature additive manufacturing. There are several commercially available printers, for example:

|

Brand |

product |

print volume |

MAX EXTRUSION TEMPERATURE |

MAX PRINT BED TEMPERATURE |

HOT CHAMBER MAX TEMPERATURE |

|

Apium |

P220 |

205 × 155 × 150 mm |

540°C |

160°C |

180°C |

|

3ntr |

Spectral 30 |

300 × 300 × 300 mm |

500°C |

300°C |

250°C |

|

CREATBOT |

PEEK-300 |

300 x 300 x 400 mm |

500°C |

200°C |

120°C |

|

INTAMSYS |

FUNMAT PRO 410 |

305 × 305 × 406 mm |

450°C |

160°C |

90°C |

|

Stratasys |

Fortus 450mc |

406 × 355 × 406 mm |

450°C |

350°C |

350°C |

|

3DGence |

INDUSTRY F421 |

380 × 380 × 420 mm |

500°C |

180°C |

195°C |

|

Roboze |

ARGO 500 |

500 × 500 × 500 mm |

550°C |

- |

180°C |

|

3DXTECH |

Gearbox™ HT2 |

457 x 457 x 810mm |

500ºC |

- |

250ºC |

Note: There are nearly 100 models of printers internationally that can 3D print PEEK and PEI, as well as other high-performance materials. This is an illustrative list. The products in the table are ranked by print volume (low to high).

But can ULTEM resin also be used for anything else in 3D printing?

ULTEM resins, given their characteristics, can also be used as parts of 3D printer components. In particular, PEI can be used as a cover layer for the print planes of FDM 3D printers.

Find out more in related articles.

Check out all ULTEM resin-based products on our website in the DEDICATED SECTION.

Need more information?

Check the product sheet for all the technical information, or CONTACT US.

ULTEM is a registered trademark of SABIC Innovative Plastics or its affiliates or subsidiaries.

Image source: SABIC, Stratasys