Features Mini Geared

Bondtech Bondtech BMG uses a 3:1 internal gear ratio along with precision CNC machined hardened steel drive gears to give you a compact power plant for all your applications. Whether you need high-resolution prints with small nozzles or high-flow prints with large nozzles, the optimized gear ratio combined with our industry-leading drive gears provides unprecedented thrust power and lightning-fast retractions in a lightweight, compact package.

Bondtech Dual-Drive

Our exclusive Dual-Drive technology delivers uninterrupted material flow even under the most demanding conditions.

Multi-material capability

The BMG extruder feeds all materials with high reliability, from slippery nylons and soft TPU/TPE filaments to highly rigid and sometimes brittle high-strength carbon-filled materials.

The extruder is designed for 1.75 mm filaments, but has been tested to ensure filament performance from 1.5 mm up to 2.0 mm allowing high reliability regardless of the tolerance of the filament used. The filament path is fully guided throughout the extruder housing and the housing maintains tight tolerances for the drive gears, decreasing the chances of filament jamming when the hotend experiences increased back pressure or highly flexible filaments are used.

Adjustable Tension

The screw tensioner allows the user to fine-tune the pressure exerted by the drive gears on the filament.

This gives you the ability to adjust according to your preferences and optimize for the type of material you're using.

Quick Release

To be able to make material changes in a snap, simply activate the Quick-Release lever to release the tension and pull the material to be changed out of the extruder, keep it activated and insert the new material.

Multi-Application Design

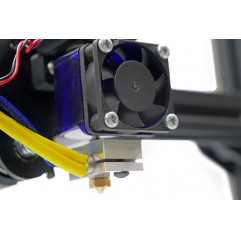

This extruder can be used in Bowden or Direct configurations, giving you the flexibility to choose what works best for your application.

It also features a built-in hotend retention method compatible with E3D-V6 hotends or others that use the GrooveMount standard. Mounting your hotend is simple, secure, and wobble-free with just two bolts.

The extruder fits any Nema17 stepper motor with a standard 5mm shaft.

This extruder is sold without a motor.

Weight without motor: 75 g

E-step Value: 415

The Motor Gear is now made of Brass

The corrosion resistant material will stop the very low frequency of oxidation problems that have occurred to steel gears.

The POM gear attached to the main shaft is now black

This is a pure cosmetic upgrade to mask the dirt that shows up too much on the white.

The Push-Fit is now threaded

It can be removed and/or replaced for ease of use without ruining the BMG housing.