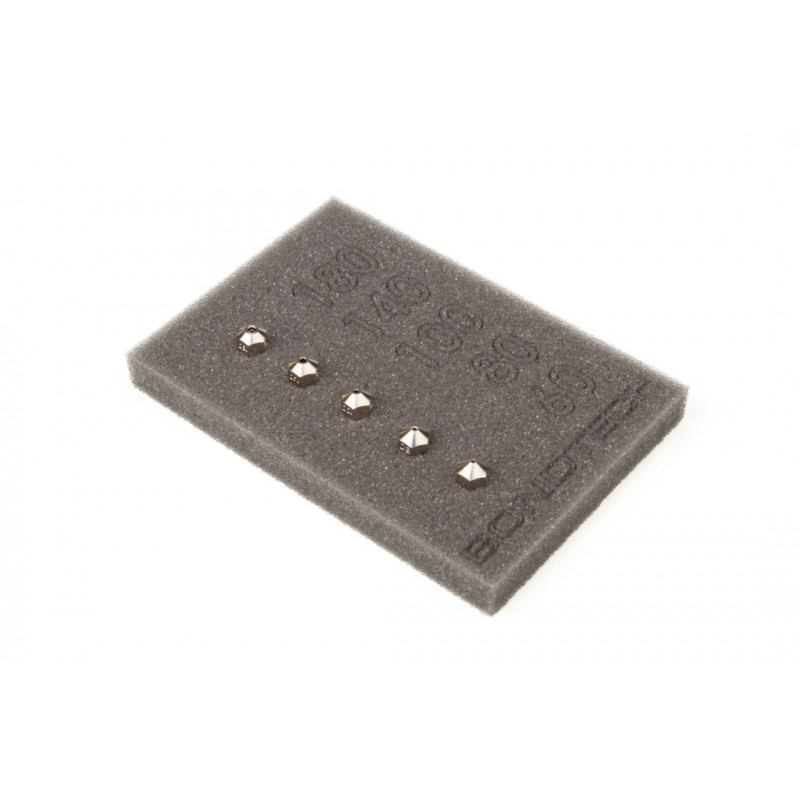

CHT Coated Nozzle - For High-Flow Applications

? Nickel plating

? Higher melting capacity

? High hot-end compatibility

These are nozzles for High Flow applications

They are manufactured in-house by Bondtech, and fit the following hotends/blocks:

? Mosquito® / Magnum

? Mosquito® liquid

? Mosquito® Magnum+

? Copperhead ?

? E3D V4, V5 and V6 blocks

? E3D Chimera and Kraken

? RepRap M6

Features

5 units per package;

Includes the following sizes: 0.60, 0.8, 1.0, 1.4 and 1.8 mm;

Optimized for 1.75 mm filament;

Compatible with 2.85 mm filament.

Key Advantages

Increased melting capacity by increasing the surface area of the heating walls

Affordable price

Machined with ultra-precision

Brass nozzle with nickel-plated surface

Follows RepRap standard (M6×1×7.5×12.5)

Can be used with 1.75 or 2.85 mm hotends.

Advantages of Bondtech CHT? technology:

The Bondtech CHT? nozzles divide the filament into 3 thinner strands allowing the material to be melted from the inside.

As a result, the material melts faster and higher flows can be used.

Core Heating is a patented technology

Registration Number: EP3445568A1

Metal 3D printer nozzles with at least one or more holes to increase the surface area of the heating walls.

Nickel Coating Benefits

A nickel coating is applied to our coated brass nozzles to provide protection against corrosion, erosion and abrasion.

Nickel-coated nozzles have greater corrosion resistance and a lower coefficient of friction, which allows for smoother material feed and delays plastic adhesion to the nozzle surface.

Recommended Materials

Use the CHT nozzle with the following materials:?

PLA

? ABS

? HIPS

? PC

? TPU

? TPE

? Nylon ?

PETG

? ASA

? PP

? PVA

For technical and abrasive materials we suggest to use a different type of nozzle.

Check out all the ones on our website!

Usage note: different sets of nozzles for different materials.

We recommend you to have different sets of nozzles because:

Using different materials with the same nozzles will cause deposits to form inside the nozzle.

These deposits will cause blockages.

We recommend changing nozzles when changing materials.