PEI surface plate with one textured side and one smooth side - printers Voron

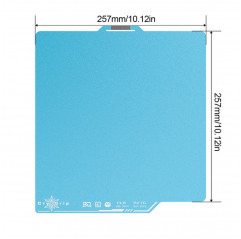

The flexible platen system DHM-pro is a printing platen upgrade for your 3D printer Voron. With different sizes available (120x120mm - 250x250mm - 300x300mm - 350x350mm), it can be used on many printers beyond Voron.

With a PEI surface coating, it offers better adhesion and easier removal of the printed pattern.

It allows a two-layer system to be created in conjunction with the dedicated magnetic platen. It is easy to install and provides strong adhesion to many materials.

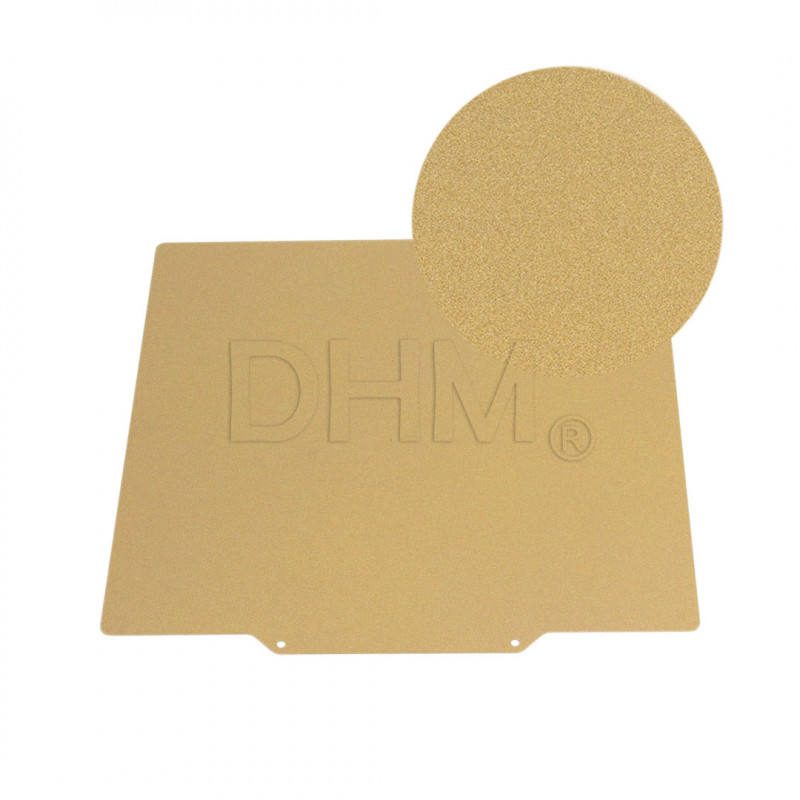

The plate features a textured side and a smooth side. It can be used as a printing plate on both sides.

It is a flexible harmonic steel plate, which does not deform when bent. In fact, when bending is reduced, the plate returns to its original state (if the yield point is not exceeded).

After printing and cooling of the heated plate to room temperature, therefore, the flexible construction board can be detached from the magnetic base. The printed pattern can then be more easily removed by gently bending the plane.

For the textured surface achieved by powder coating applied directly to the metal makes it very difficult to damage the printing platen. The powder coating also gives the surface a textured appearance that will be visible on the base of the prints. The textured surface hides most of the mechanical damage caused by the tools usually used to remove printed objects.

The powder-coated PEI mat is heat resistant up to 200°C.

During printing, the coating on the printing surface ensures excellent adhesion.

This type of plate is the best solution for printing PLA and has excellent adhesion with almost all materials. The bottom of your prints if you use the smooth surface will be smooth, otherwise if the textured side is used the surface of your prints will be slightly knurled.

Key Features.

- Print plate: textured PEI

- Excellent adhesion

- Many compatible materials: suitable for PLA, ABS, TPU and PETG

- Sizes: various models available

- Quick and easy installation: the steel plate is placed over the magnetic plate and remains fixed to

- Uniform heat transfer

- Maximum temperature of the heating bed: 120-130 °C

Advantages:

- Scratch-resistant, difficult to damage

- You can decide the printing side

- More adaptive Z adjustment

- No need to apply adhesives for PETG

- Prints come off automatically as soon as the platen cools down

- The first layer can be flattened more than smooth sheets

Disadvantages:

- PLA prints with small contact areas may require a brim

- PLA prints with a large contact area may warp

Usage temperatures:

- PLA: 40°c - 60°c (60°c is recommended for objects with a large base)

- PETG: 75°C - 85°C

- ABS: 90°C - 100°C

Notes:

To ensure a longer shelf life and avoid damage to the prints, we recommend waiting for both the shelf and the printed object to cool down by reaching room temperature.

The PEI top can be cleaned using 90% isopropyl alcohol (IPA).

Caution.

Never use acetone to clean the rough PEI powder coated flexible steel plate! In fact, acetone creates micro-fractures in the PEI texture, which leads to deterioration of the surface over time.

Do not wash the PEI top with water. Wait for the plane to cool before removing it from the printer and folding it to remove the printed piece. We do not recommend using tools to remove printed pieces. For example, avoid using spatulas that can damage the surface of the platen.

Package contains:

1 x PEI surface plate with one textured side and one smooth side 120 x 120 mm

Magnetic sheet for fixing is to be purchased separately.