Founded in 2014, in Grand Rapids, Michigan, 3DXTECH brings innovative, high-performance materials to the filament additive manufacturing industry. With a focus on functionality and a creation process based on more than 25 years in the 3D printing industry, 3DXTECH filaments are created using state-of-the-art equipment and processes.

A team of carbon fiber experts.

This ensures that consumers receive the best carbon fiber 3D filaments on the market.

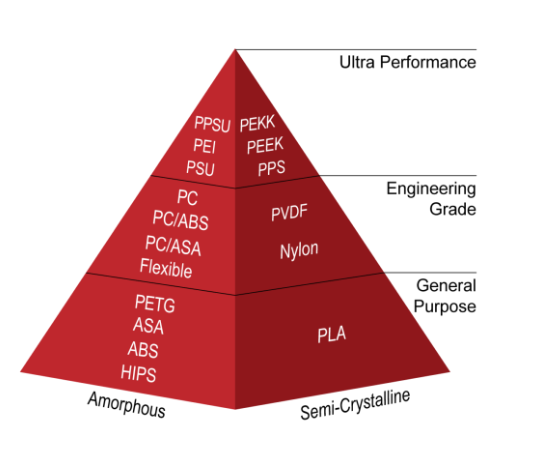

Among the filaments offered by 3DXTECH are

- PLA

- PETG

- ABS

- ASA

- HIPS

- Flexible

- Polyethylene [OBC]

- Polypropylene [PP]

- PC/ABS

- Polycarbonate [PC]

- Nylon

- PPE/PS

- PVDF

- PPS

- PSU

- PES

- PPSU

- TPI [Extem™]

- PEI [Ultem™]

- PEEK

- PEKK

- Support filaments

We know that not all materials are suitable for all printers, and novice end users often have more difficulty than someone with much more experience. Being able to use certain materials with specific technical characteristics to achieve prints of a given quality involves experience and machines of adequate performance.

Hence a general-level outline of the expected difficulty with a given filament.

The breakdown comes from many years of printing experience, as well as from solving problems with our customers.

3D printer experience levels

- Beginner: a beginner using an entry-level 3D printer should have minimal problems using this material

- Intermediate: the user has several months of experience with a moderate to high quality 3D printer

- Advanced: the user has > 1 year of printing experience and is using a high quality commercial machine

- Expert: the user has significant experience and is using a high-performance or heavily modified 3D printer

Need technical support?

Check the product sheet for all technical information, or CONTACTUS

Follow our socials to stay up to date with the latest news!

CREDITS @3DXTECH