A first look at the kit DHM step by step Voron 2.4: a high-performance CoreXY

Here is the BIG news that many of you have been waiting for!

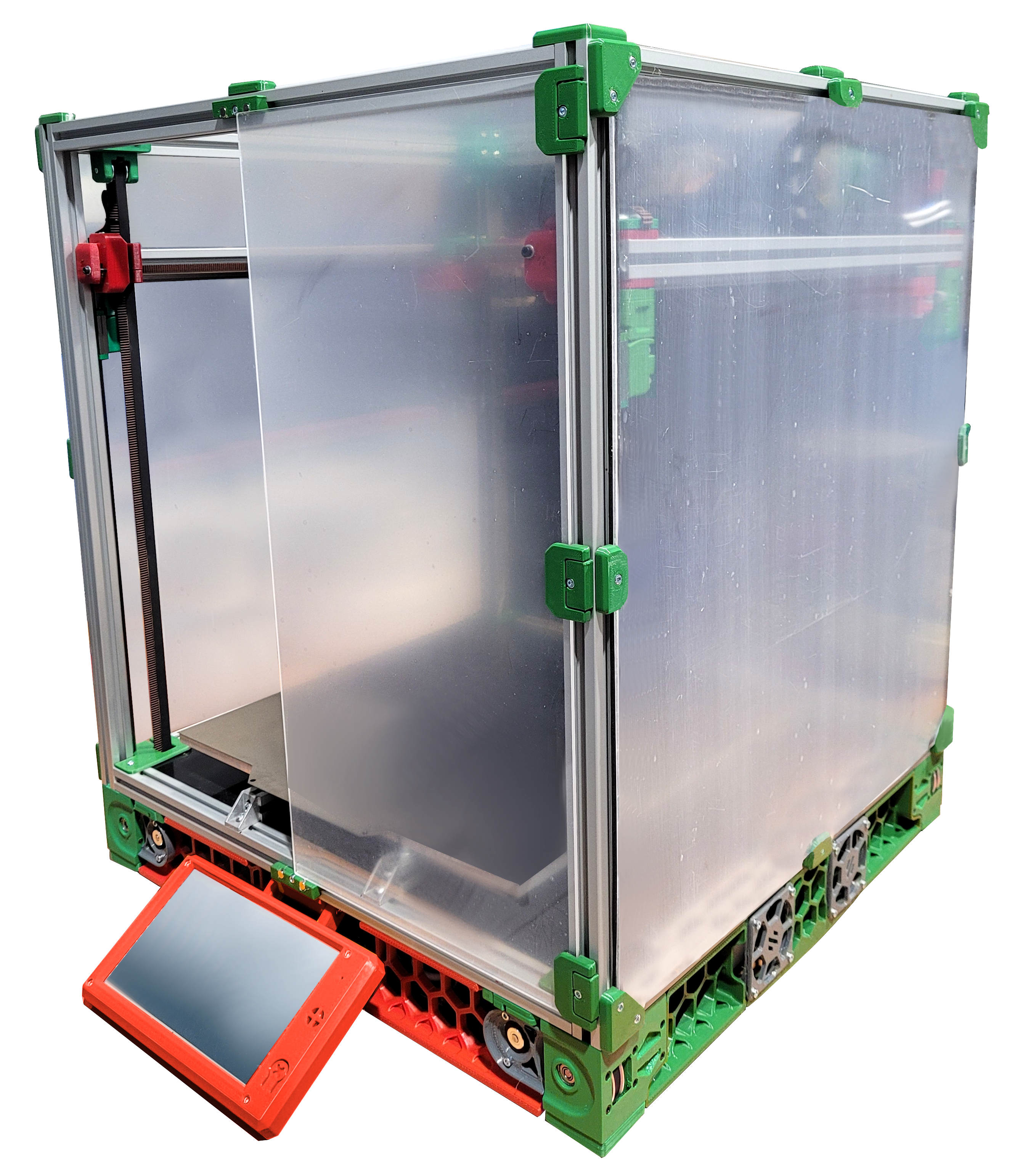

The first step by step kit of the Voron 2.4 made by DHM: a high-performance CoreXY 3D printer.

There are some exciting features in the Voron 2.4 printer. Let's get into the details because it has more than just a large print volume!

Our team has evaluated every aspect of the machine by following the official guide Voron, but choosing first-rate materials and incorporating small improvements that come in handy during assembly and use.

Why?

So many of you have already asked us many questions, and almost all of them start with why?

Why a kit divided by step? Why not a single kit like the import kits ? Why not all step come out together? Why not an inexpensive kit ? Why have we waited so long to see these kits online?

Let's start from the beginning...

The DHM team gets to know the project Voron in 2019, but it is not until 2020 that they begin to delve into its ecosystem. In fact, it is in 2020 that we have the worldwide explosion with the release of no less than 5 printers: the V1.8, the V2.4, the Switchwire, the V0 and the Legacy. Our customers ask for the first components, and so begins our journey of research and in-depth study.

Our team did not want to leave anything to chance, so we assembled more than one machine and tried different components, to offer our customers the best.

The Voron Design team members gathered in the "sourcing guide" almost all the material needed, but having to retrieve it from different suppliers in different parts of the world (if they can be retrieved at all) is quite a feat.

The first Chinese-sourced kits came out, but after testing them and collecting various user opinions, we have decided: we propose a kit Voron made by DHM.

First-rate components from certified manufacturers (no clones) or self-made and preparation made in Italy.

"Less is more"

But not in quality

Kit Voron made by DHM

We decided to start with the Voron 2.4 kits as the model found to be the best performing in our tests.

The kits include 9 steps and in each of them you will find ALL the components for assembly accompanied by a manual with instructions and construction cautions to self-build a 3D printer Voron 2.4 according to the official project of Voron Design.

The DHM kits come from our experience in the 3D printing industry and knowledge of quality manufacturers. In addition, thanks to our in-house workshop, we created custom components by making small improvements to the design to give optimal reliability and performance.

The idea of the Voron kits made by DHM is to follow the assembly path step by step, and not offer like many, the kit divided into "mechanical" or "electronic," etc.

By following STEP by STEP the assembly in fact you have the overall view of the printer taking shape.

The steps are complete with all the components, and with the contents of one step you are able to fully assemble a specific part of the machine. For example, step 1 includes the frame components and the Z-axis linear guides including all the small parts needed to assemble the frame.

This way you do not rely on low quality or incomplete ready-made kits, nor do you have to resort to "Sourcing guide" to retrieve component by component without having the complete picture.

We will release approximately 1 step per week, but we are also working on a single bundle, given the many requests received these days.

We have already tested the installation system by following the PDF manual that comes with each step. It is "easy" to complete the installation without any hiccups if followed to the letter (the manual corresponds to the official Voron Design guide with some additional tricks).

The first assembled model

Despite this, since it is a printer supplied as a DIY kit with many components it is not considered an entry level machine. We recommend choosing it for users who are already experienced, or if new to the world of 3D printing to have adequate technical application knowledge.

Packaging to size, code and work list management allows for orderly assembly without too much difficulty.

There is already a lot of material online that offers additional help during assembly: from the official guide Voron Design, to the many YouTube videos of the most followed channels on 3D printing.

Starting with NERO 3D which is part of the Voron team at Thomas Sanladerer, one of the most followed channels for 3D printing in Europe. Even here in Italy something is moving, in fact the reference channel Help3D, has chosen our kit to build its own Voron 2.4. So you will soon see some quality content in Italian language as well.

Upgrades of already assembled Voron 2.4 printers

No less important is the fact that the division into step allows quality upgrades to existing machines.

It happens in fact that some kits already existing on the market sin in some aspect, such as in the printing plane, rather than in the quality of the panelling or linear guides. In other cases some essential components are absent, such as thehot-end or the control board.

The Voron 2.4: the CoreXY printer in large kits

The Voron 2.4 is officially presented in 3 versions that differ in print volume:

Kit Voron 2.4 250 mm → 250x250x250 mm

Kit Voron 2.4 300 mm → 300x300x300 mm

Kit Voron 2.4 350 mm → 350x350x350 mm

The team's favorite DHM is undoubtedly the 35cm3 model since the two smaller 25cm3 and 30cm3 models planned for Voron have basically the same components (only some scaled down in size) and the price will not be much different from the larger model.

The 35cm3 size (about 13.78" cubed) is ideal for keeping vibrations under control, having a large print area for printing large objects in one piece, as well as reproducing detailed models.

Can one go beyond the 35cm model to have a larger print volume? There are already some proposals in the Voron channel, but as print volumes increase, CoreXY printers are becoming increasingly difficult to build, set up, operate and maintain. So we are carefully considering possible proposals.

Kit Voron 2.4 made in Italy by DHM: the key components of several STEP

What characterizes our team is the search for the quality component, which comes from the now 10 years of experience in the world of 3D printing. Let's discover the key components of this project.

Linear guides DHM pro

The linear guides included in the Voron 2.4 kit are from the MGN series of our DHM pro line. These are hardened stainless steel linear guides. The MGN series features guides with a compact, lightweight shape suitable for small but high-precision devices.

Comparable in technical specifications to those of leading brands such as HIWIN, Bosch Rexroth, THK, and ROLLON, the DHM pro linear guides are the professional series of our linear slide guides.

They are characterized by:

- Load coefficients equivalent to existing professional products on the market;

- Good vibration absorption capacity;

- Compact design for mounting even in small applications;

- Low coefficient of friction.

Linear guides DHM pro can withstand vertical and horizontal loads. In addition, due to the circular arc groove design, they can withstand the preload required to increase rigidity. This results in high performance, higher precision and better efficiency.

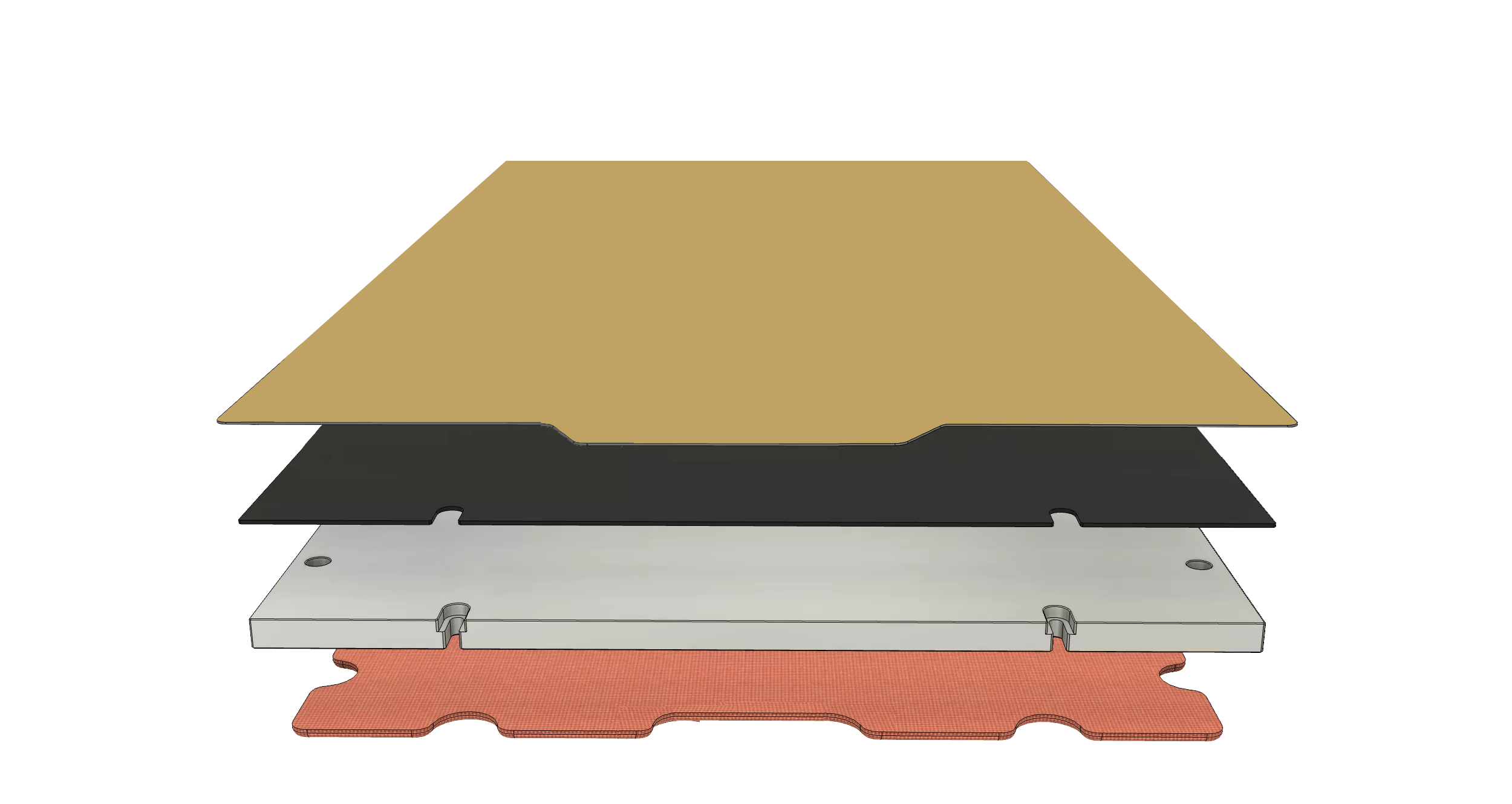

Ground printing table with PEI-coated printing base

The printing table supplied with the kit consists of several layers, each with a very specific function. Starting from the bottom we find the Arlon silicone pad. This heated silicone pad features an EPCOS100K temperature probe and an included 150° thermostat. The recommended operating temperature is between 60°C and 150°C. It operates on alternating current (220V AC) and features a high-temperature resistant power cord protected by a fiber braid.

The silicone pad connected by adhesive to the aluminum plate allows it to heat evenly to maintain adhesion of the first printing layer and avoid deformation to the object being created.

The plate supplied with the kit is a CNC ground and milled EN 5083 cast aluminum plate.

The slot and hole design is specially designed for the 3D printers Voron.

We next find in succession the magnetic base with the PEI textured harmonic steel top. The magnetic base has the adhesive to mount it on the aluminum top. The harmonic steel top can then be placed on it and will adhere to it due to the magnetic force.

The PEI coating of the plane then allows for good adhesion of the first layer, without having to use any special tricks.

Belts and pulleys to ensure reliable motion transmission

The Voron 2.4 kits include belts and pulleys for motion transmission. The belts, in particular, are from Gates' PowerGrip® line.

PowerGrip® belts feature trapezoidal-shaped elastomer teeth that are extremely precise and carefully spaced to allow perfect engagement with the pulley grooves. The tensile strands are made of fiberglass to provide high strength. They also feature a nylon coating to protect the tooth surfaces.

This model of Gates belts can work at speeds up to 10,000 rpm, with peripheral speeds up to 80 m/s (80,000mm/s).

No lubrication or retensioning is required, which allows for operational continuity during printing. The operating temperature ranges from -30°C (-22°F) to +100°C (+212°F), so it can be used without problems in the hot chamber created in the Voron 2.4 enclosed by the panels.

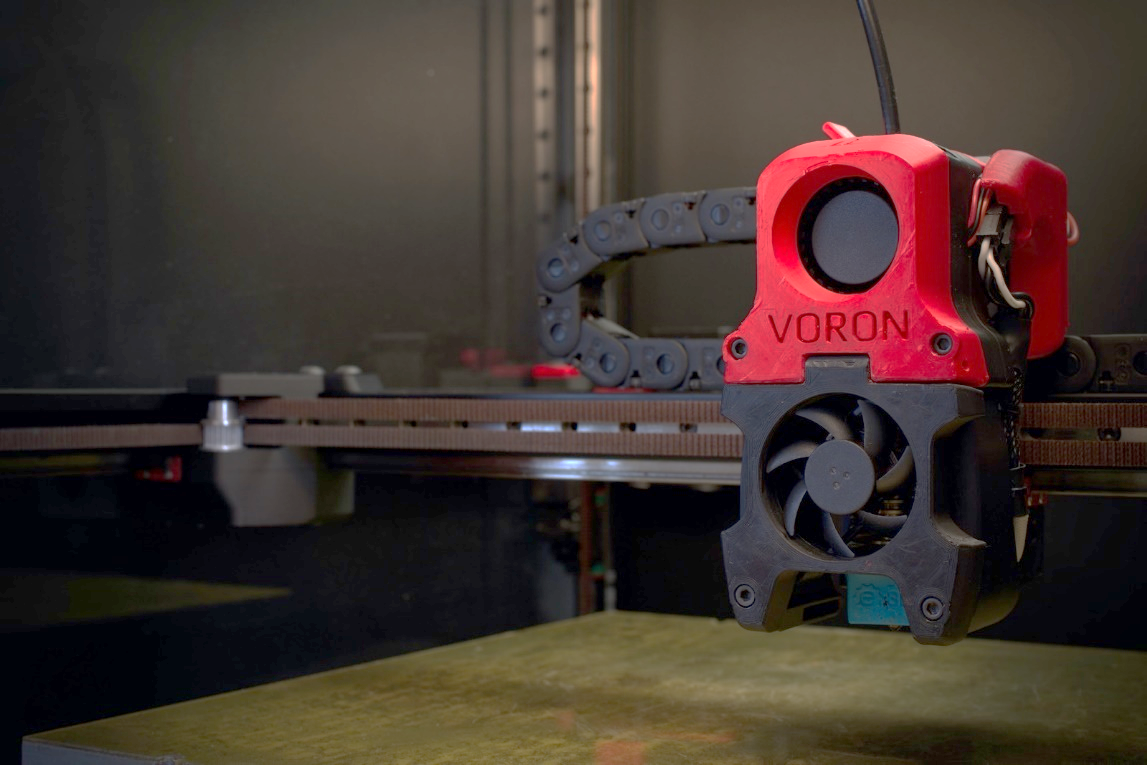

Extruder assembly Afterburner: compact and functional

The kit Voron 2.4 DHM presents several options in the choice ofhot end. The extruder assembly provided by default is theAfterburner with the original gears Bondtech.

The Afterburner head of a Voron printer consists of a few main parts. The Clockwork, a direct drive extruder, the hotend assembly with the fan and the mounting carriage on the linear guide.

It is a very compact direct drive extruder assembly that can travel at a sustained working speed due to its design.

Different types of hot-end can be mounted. We offer the following alternatives in our kit:

- Dragonfly BMO (Phaetus) - for those who want an entry level hot-end, but still gives satisfaction

- Revo Voron (e3D) - for those who like e3D and for those who want to try the RapidChange function that allows you to change nozzles quickly without the use of tools or hot screwing (unfortunately, at the moment only available in the brass version)

- Mosquito (Slice Engineering): for those who want to take it to the next level with technopolymer prints up to 300°C with the included thermistor, with the highest print resolution thanks to Bimetallic Heat Break™ technology, with the lowest mass to hook up to gantry for maximum X-Y acceleration

First-rate electronics

MEAN WELL Power Supplies

Included in Voron 2.4 kits made by DHM is an original Mean Well power supply. These power supplies are distinguished by their high reliability. In fact, the manufacturing process is characterized by very strict safety, efficiency and quality procedures, so that the end user is guaranteed a sophisticated and long-lasting product that meets all prevailing standards.

Engines WANTAI

We have been cooperating with Wantai for many years now. WANTAI MOTOR is a professional manufacturer of stepper motors, as well as hybrid stepper motors, brushless DC motors and related drivers. High quality motors with global standards that are perfectly suited for use on 3D printers.

Control electronics DUET3D

Why DUET 3D? We decided to include Duet 3D electronics by default because we have been using these products for some time and believe they offer many features suitable for a printer Voron.

The board used is based on a 32-bit ARM processor, running RepRapFirmware. The Duet family can be controlled via a Web interface, but it also supports a touchscreen (PanelDue) that can be of different sizes. Of course, being official distributors for Italy, the boards and components Duet3D included in the kits are strictly original.

We will delve into the electronics issue in another article and see the various possibilities available with their pros and cons.

OMRON sensor and relay

Regarding the proximity sensor to be installed to perform the plane alignment, we chose Omron's TL-Q5MC2. This sensor has the special feature of having a heat-resistant ABS case, so compared to other sensors that can be found on the market it is less likely to melt. It works, in fact, in very close contact with the heating block ofhot-end.

Another component, which is small but essential, is the relay to be used to manage the printing table. Care must be taken with the relays used, because if they are of poor quality they can go to create safety problems when the machine is running.

Top options

Plastics

Some components are available as optional extras. In the kit, it will be possible, for example, to choose whether or not to provide printed parts.

In fact, many users already have a printer available to self-produce the plastics needed for assembly.

Alternatively, you can choose to include the molded parts from our machines. Plastics for Voron 2.4 will be supplied in Nylon Carbon to ensure reliability at the most critical and structural points, and in ASA. ASA is a tough and resilient material that, due to its UV and temperature resistance (up to 93°C), is suitable for outdoor use and for making technical parts. In addition, it is available in various colors, thus allowing customization of aesthetic parts.

Made-in-Italy wiring ready and cut to size

The cables supplied with the Voron 2.4 kit are made in Italy, sized according to the power used and suitable for the function. The option of having the cables pre-crimped and sealed is provided, for those who do not have dexterity in wiring or want to choose a faster option. Wiring is one of the most serious aspects of construction and it is important to do it well, which is why there is so much focus on providing a high-quality option.

Bottom line.

If you are left with questions or concerns check the individual component descriptions for technical specifications, or contact us.

The kit to build your next 3D printer is waiting for you!