What is Voron 2.4?

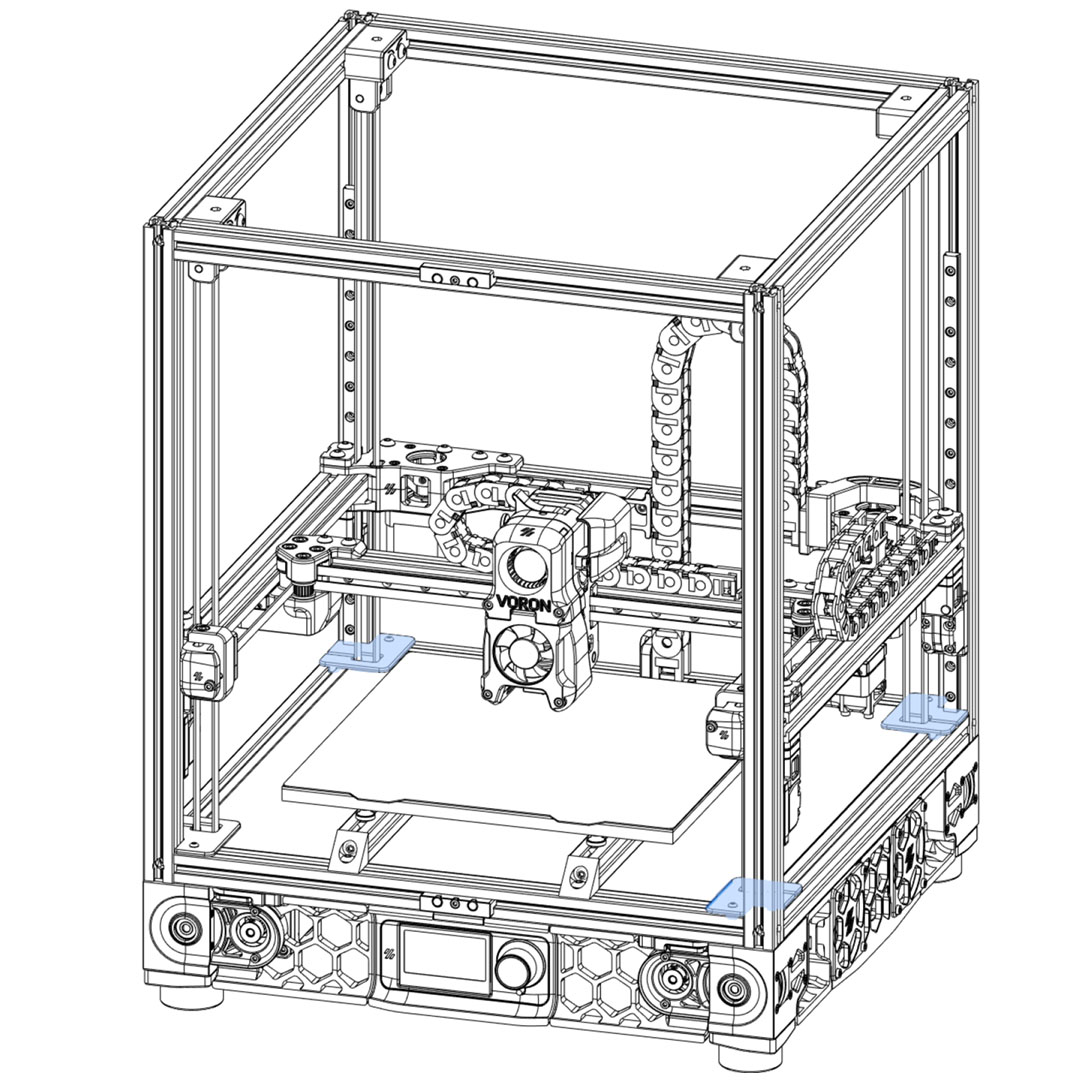

Let's pick up the topic Voron by talking specifically about the most talked about of the family: the Voron 2.4.

The Voron 2.4 is a motion-controlled 3D printer design CoreXY with a fixed plane designed by Voron Design. This printer is known for its reliability and high performance.

So let's look at it specifically and whether it is worth building a 3D printer with this configuration.

A 3D printer CoreXY that has few equals

Staying true to the fundamentals of the RepRap project, the Voron 2.4 is completely open-source, customizable and self-buildable.

The Voron 2.4 is composed of 3D printed components as well as a number of mechanical and electronic components. Don't worry, though: Voron has thought of everything. You can find all the assembly information at Voron and follow the instructions for the BOM (bill of materials) and assembly.

Key features of the printer Voron 2.4

In summary, what are the key features of the Voron 2.4 model?

- Model: CoreXY modified: the system belts do not cross, but work on two separate levels;

- Frame: Aluminum profiles with 3D printed parts;

- Variable build volume: 250 mm3 - 300 mm3 - 350 mm3;

- Extruder configuration: Direct;

- Extruder: Bondtech BMG extruder (3:1 gear ratio);

- Hot-end: customizable - compatible with most hot end on the market;

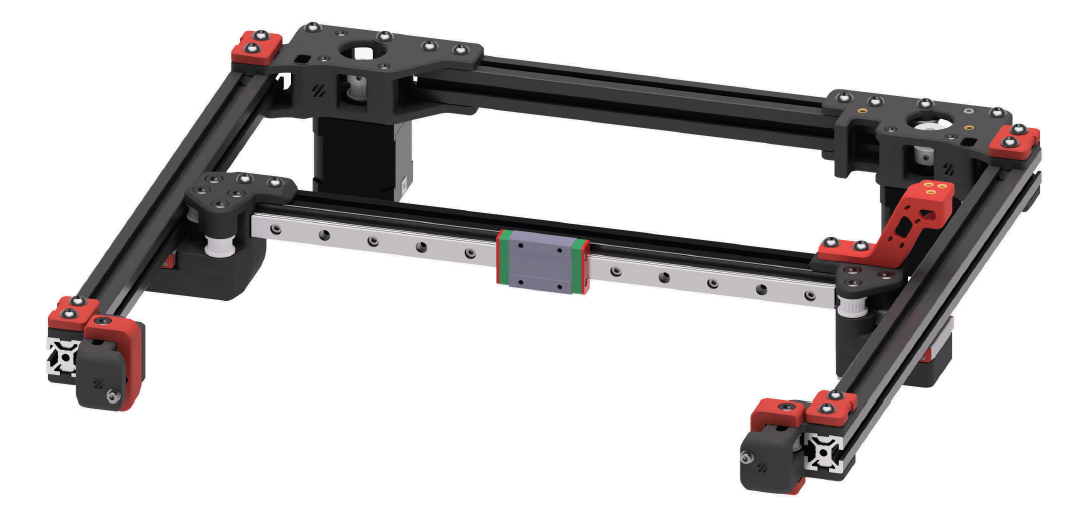

- Drive system: 2GT belts and linear guides for X and Y axes and Z axis;

- Plane leveling: Automatic leveling by inductive probe;

- Stepper motors: NEMA 17;

- Voltage: 24V DC and 220V AC for heated plate;

- Motherboard: customizable (standard version includes Raspberry Pi + BTT Octopus);

- Printing surface: magnetic plate with PEI Sheet.

The bill of materials is available on the website at Voron, and you can choose various options for the Voron you intend to build, such as Direct or Bowden feeding and even the size of the printing surface.

There is provision for a static bed and a gantry that moves along the Z axis. This is a much more complex construction than other models Voron because it includes elements such as traming the 4-point gantry to align with the printing surface.

Frame and motion transmission

The Voron 2.4 is a reliable printer, so naturally the machine's chassis is quite sturdy. The Voron 2.4 features, like the other models in the Voron family, an aluminum profile frame. The 2020s are used in this model, as also for the Voron Trident .

The Voron 2.4 uses a Cartesian motion system CoreXY, in which the carriage with thehot end is connected to a group of belts, pulleys and supports to move along the X and Y axes pulled by two motors synchronized with each other. This motion system CoreXY also moves along the Z axis so that the printing table never leaves its position.

An important aspect is the printing plane. Given its conformation as a static table, the Voron 2.4 is ideal to be used with a ground aluminum printing table. This can also be of generous size and thickness. In fact, since it is attached to the profile structure, it does not encumber axis movements in any way; on the contrary, since it is positioned low, its mass helps to keep the structure's center of gravity low. A magnetic base with a PEI-coated harmonic steel top can be installed on it in sandwich mode.

The Voron 2.4 for all movement on the X, Y and Z axes relies on linear guides in association with GT2 belts. This configuration of gantry allows Z-axis movement on the four corners. This allows the machine to self-level by raising or lowering each corner relative to the underlying print bed based on feedback from the printer's built-in leveling probe.

A unique print head

Voron developed a special design for the printhead with direct extrusion mechanism. The name of this printhead is Afterburner. It is the set of molded parts that allow thehotend and extruder to be supported on the gantry.

Afterburner comes in different versions because it allows you to accommodate different hot end depending on your choice, needs or preferences. The Afterburner system has three interchangeable components: the extruder, the lower support that houses thehot end and the cooling unit.

This printhead is complex to assemble because it involves several components, both 3D printed and hardware and electronic.

In fact, all the components necessary for printing are installed inAfterburner, in particular let's remember that the cables of: extruder motor, heating cartridge, thermistor, heat-sink cooling fan, print cooling fan, probe probe and any accessories such as wire end sensor and LEDs pass through here.

In short, quite a lot of cables that we will see in the next articles how best to order and manage them, simplifying and reducing theAfterburner connection to 4 wires.

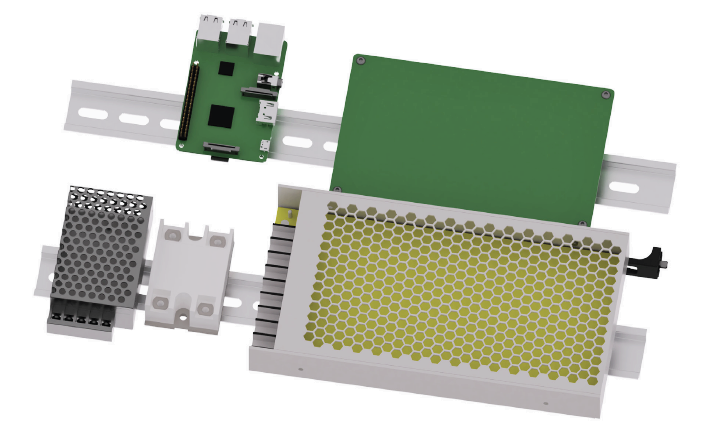

Electronics

The Voron 2.4 features several electronic components. Here are the main ones:

- 7 nema17 stepper motors;

- 5 cooling fans;

- 3 limit switches;

- an inductive leveling probe;

- a hot end;

- a resistor for the heated plane;

- a control board;

- a display;

- a DC power supply;

- etc etc.

Each of these components requires a specific output/input on the motherboard. In particular, let us focus for a moment on the management of the z-axis with 4 independent stepper motors. This system requires continuous calculation of step for each individual z-motor in order to maintain a constant distance between the nozzle and the print bed during movements along XY. This is one of the most fascinating features of the 2.4 but at the same time it is the most onerous in terms of computational calculation of the microsteps from gcode obtained from slicing. Therefore, Voron 2.4 needs high computational power compared to a normal Cartesian in order to handle all inputs and outputs continuously.

There are varies options that can be used for control boards, and we will discover them later by analyzing the pros and cons of each.

So sign up for the newsletter to keep up to date!

Firmware

"All Voron printers work with Klipper firmware."

True, but not very true. You can also use other firmware open source with just as many advantages.

In addition, there are also several web interfaces available for printer management, which we will explore along with alternative firmwares in one of the upcoming focuses at Voron.

The Project Voron recommends using Mainsail or Fluidd, although Octoprint can also be used. Mainsail and Fluidd are both developed specifically for Klipper-based printers, while Octoprint is a more general-purpose platform.

Clarification: Klipper is usually installed on a computer external to the motherboard to relieve it of the computational load for processing G-code. Usually a Raspberry Pi4 is paired with the Bigtreetech board, which takes over the management and G-code passing motion commands directly to the board.

You can then print faster by taking advantage of the Raspberry's CPU.

Is it worth building a Voron 2.4 printer?

The Voron 2.4, given all the features we have discussed is the most expensive model in the Voron family, but its features are unmatched. It takes a lot of concentration, but the effort will be worth it.

If you follow the construction guide with all the directions and if you calibrate the machine properly, then you will get an accurate and reliable printer.

Let's take a look at a roundup of the strengths and weaknesses of building a Voron 2.4.

Let us start with the most critical aspects, because, it is never like fairy tales.

Critical points:

- The assembly of Voron 2.4 has a high cost, mainly due to the quantity of components. If material quality choices are made, the cost increases considerably.

- The wiring and electronics management aspect makes building a Voron 2.4 more suitable for experienced people.

Strengths:

- Many owners, if not the vast majority, have praised the Voron 2.4 for its reliability and speed.

- Customizable in many ways, from aesthetics to choice of size, type of electronics, extruder, and many others.

- The structure based on aluminum profiles is easily scalable to the size you prefer.

- Direct drive is best for printing flexible filaments (such as TPU). Contraindication is the weight of the printhead that burdens gantry, but that is why the system of Afterburner, which is sturdy and compact and allows for agile printing even in direct, was designed.

What if you want to start building one?

Don't worry, our team joined community embracing the Voron project and built several examples of these 3D printer models so that we could evaluate firsthand the difficulties, critical components and software development to best support you at every stage.

After careful evaluation, we decided to implement a dedicated section on our website dhm-online.com where you can find all the components needed to build a 3D printer Voron.

This is because we found firsthand difficulties in sourcing materials when building our first machines. Even in the kits sold as complete, or nearly complete, we pointed out gaps. Moreover, in the official discord channel (https://discord.gg/voron) several users have also pointed out critical points for each of the different kits currently on the market.

Therefore, using our extensive network of suppliers and partners on a global scale, which allows us to produce and select high quality products, we are making all tested and proven components available to the end user in one place where reliability and service is guaranteed.

In addition, with our in-house workshop we have the ability to create custom components thus making continuous improvements to the design.

Products can be purchased by both individuals and businesses, there are no minimum quantities, but rather, various discounts are provided if multiple orders are placed or through our loyalty program.

Thanks to a strong network of logistics services, we ship our components all over the world. Starting from the national territory Italy, and moving on to Europe and worldwide.

So what are you waiting for?

Check out the new section being updated:

https://www.dhm-online.com/en/s/3/components-and-spare-parts-for-voron-3d-printers

Don't miss the upcoming news because good things are going to happen!