Why use a silicone pad for a 3D printer?

FDM (filament) 3D printer (FDM) platens, as in many other industrial applications, generally need to be heated during printing. This is to allow proper adhesion of the material as it is being deposited, but not only that.

Here are the key points why we recommend using a heated platen for your FDM 3D printer:

- Allows proper adhesion to the platen: A warm build surface prevents the extruded filament from cooling too much and too fast. This gives it time to adapt to microscopic surface imperfections and adhere better. The exact definition of "too cold" or "too fast" depends mainly on the type of material printed and the geometry of the object (for specifics on temperatures of use we recommend consulting the filament's data sheet or requesting it from the manufacturer if you do not have one).

- It helps prevent warping: As the molten filament cools, internal stresses form, particularly pronounced at corners. When additional layers of hot filament are added, the temperature difference can cause these stresses to shift inward. In turn, if adhesion is poor, corners can pull away and curl (i.e., warp - warping) upward, potentially ruining the print. Heating the bed reduces the tendency for prints to warp by equalizing the temperature difference and holding the print with better adhesion.

- Facilitates print removal: When the print is finished and the heated bed cools, the lower layers of plastic contract a little more, become stiffer and loosen their grip on the bed. With most materials, this helps the prints come off cleanly from the printing surface and leave no residue on the bed.

- Creates a heated environment if the printer is closed: The heat generated by the platen is dissipated to the surrounding environment and helps keep the entire build volume warm, especially if it is closed. This reduces excessive cooling stresses for all layers of the print, thus improving the quality of the entire object being made.

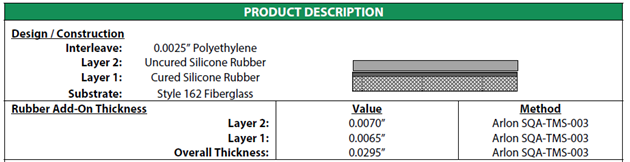

There are different types of heated printing pads, we will look here specifically at Arlon 27CR silicone rubber pads.

These silicone pads are particularly convenient because of the ease of installation using 3M adhesive. In fact, they can be applied directly underneath the existing build deck and thus make a previously unheatable deck heatable.

They are professional products with both high thermal and durability performance as we will find out specifically with the technical data below.

Unlike other silicone countertops that subjected to high temperatures and mechanical stress due to thermal expansion lose their physical properties, these even above 200° C manage to keep their properties constant.

We recommend them for installation on 3D printers and beyond given the wide use of these products in robotic systems, there where constant temperature control and maintenance is needed.

In particular in our e-shop you can find dedicated sizes for the entire range of 3D printers Voron especially for the models: Voron 2.4, Voron Trident , Voron 0.1.

Arlon 27CR: what is it?

Highly thermally stable flexible heater compound recognized by UL

Arlon is a registered trademark of the American company Rogers Corporation. They are flexible heater substrates and set the industry standard for high-performance silicone heater insulation.

For many reasons, we chose Arlon as the material for our 3D printer heater plates in the DHM pro line.

They are made of thin, flexible silicone rubber composite materials and fiberglass fabric. These substrates are UL-rated, thermally stable, highly conformable and customizable. ARLON flexible heater substrates have earned a reputation for reliable performance and long life in wire and etched foil heater applications.

Intro

Arlon has a higher resistance to thermal aging than products currently on the market. Compound 27CR and calendered flexible heater substrates have demonstrated superior thermal aging resistance through rigorous analyses, including retention of long-term properties during accelerated thermal aging.

Long-term thermal stability with good tensile strength and dielectric strength retention has been validated through the UL746B program.

Most silicone pads lose a large percentage of tensile strength, elongation, dielectric strength, and adhesion strength at elevated temperatures, especially above 200°C.

Arlon 27CR flexible heater compound is designed to ensure thermo-oxidative stability so that coated substrates remain flexible.

Thermal Resistance

Thermal stability is a key feature of flexible silicone tops due to exposure to a wide range of temperatures.

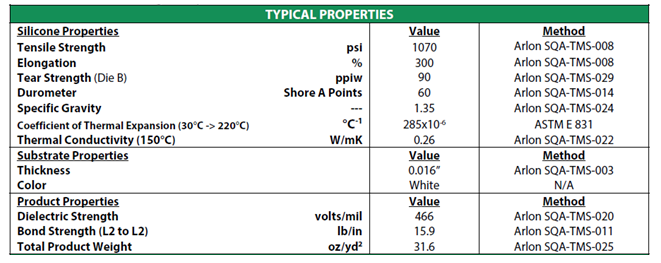

They must be able to maintain key material properties such as tensile strength, elongation, dielectric breakdown, and bond strength at these elevated temperatures for extended periods of operation.

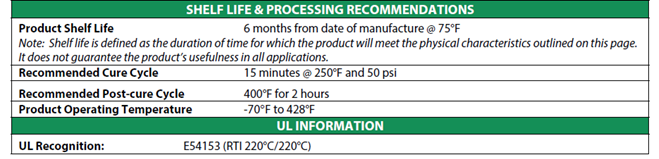

Compound 27CR and coated substrates were tested by Underwriters Laboratories and achieved a Relative Thermal Index (RTI) of 220°C/220°C (electrical/mechanical evaluation) according to UL Card E54153.

Short-term resistance to overcrosslinking

While most silicone compounds begin to over-crosslink at temperatures above 200°C, resulting in a loss of tensile strength and elongation, Arlon's compound 27CR maintains these key properties at higher temperatures.

Graph 1 shows that the 27CR product retains more than 95 percent of its tensile strength when exposed to temperatures above 250°C for one week. It also loses virtually nothing in tensile strength when subjected to 320°C for 24 hours.

Key features:

- UL-recognized relative thermal index (RTI) up to 220°C

- Thermally stable up to 232°C (450°F) continuous operation; up to 316°C (600°F) intermittent

- Rated for horizontal (UL 94 HB) and vertical (UL 94 V-0) combustion

- High dielectric strength, withstands 400-600 volts per mm thickness

Advantages:

- Resists corona and arc damage

- Environmentally stable: resistant to ozone, moisture and environmental chemicals

- Bondable to most surfaces, using specific primers or 3M high-temperature adhesives

- Easy to fabricate and install

- Highly customizable

Learn about the silicone plates in the DHM pro line in the dedicated section.

Need more information?

Check the product sheet for all the technical information, or CONTACT US.