Are you familiar with the DDX direct extruder developed by Bondtech for Creality?

Bondtech created an upgrade path Creality step-by-step.

You start with step 1 and can proceed up to step 4, depending on your different needs. The DDX has perfect compatibility, easy installation and an open door to evolving your Creality.

So far the DDX is compatible with 16 different models Creality. The most popular option is to use the DDX PHase 1 with a PHase 3 upgrade with Mosquito.

The DDX v3 version, in particular, is compatible with many models and features a new and much simpler configuration process.

MORE MATERIALS, MORE APPLICATIONS, MORE VALUE

"Materials drive applications. Applications generate revenue, profit and value. The more materials a user can process, the more value they can extract from their 3D printer." Bondtech

This extruder upgrade kit comes with all the parts needed to upgrade a 3D printer Creality from bowden to direct drive. With the DDX extruder, the range of materials that can be used can be expanded.

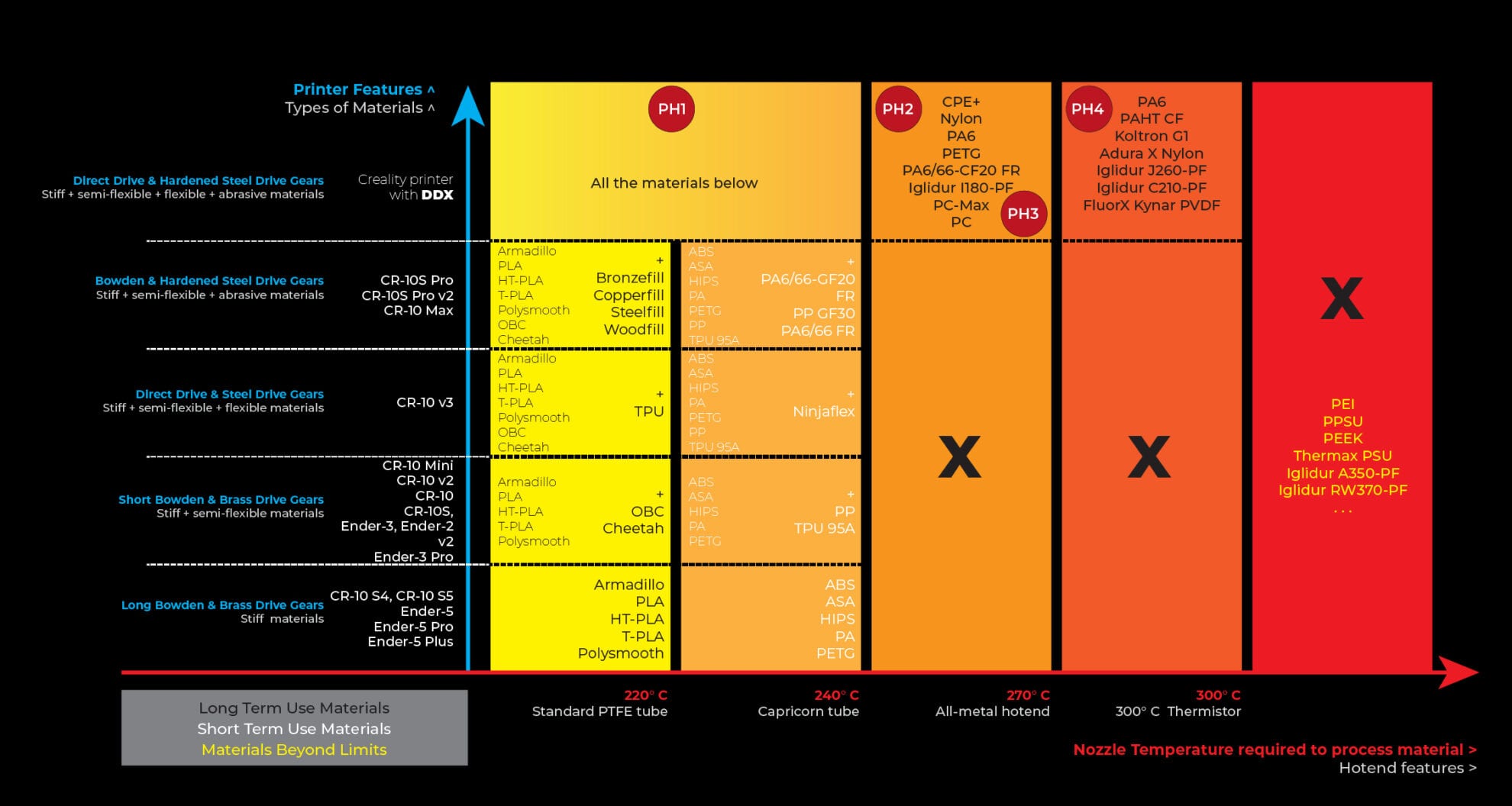

For example, with a PH1 upgrade (phase 1) you can print filaments up to 240°C (with Capricorn tube), for example ABS, ASA, HIPS, PA, PETG, as well as standard PLA, HT-PLA and many others depending on your configuration.

Here is an example schematic of the capabilities of your Creality.

Note: The above table is only a guide with a limited number of examples. It is not a guarantee of performance or compatibility. Different hardware configurations and materials require different settings and adjustments. Results may vary.

PH1 > Phase 1

A phase 1 upgrade mounts the DDX extruder from Bondtech: Direct Drive eXtruder.

Main features of the phase 1 upgrade:

- No firmware upgrade required

- Increase the range of printable materials

- Enjoy the reliability of the Bondtech mini geared BMG

- You can reuse the stock components of your Creality: hotend, nozzle, thermistor, heating cartridge, fans.

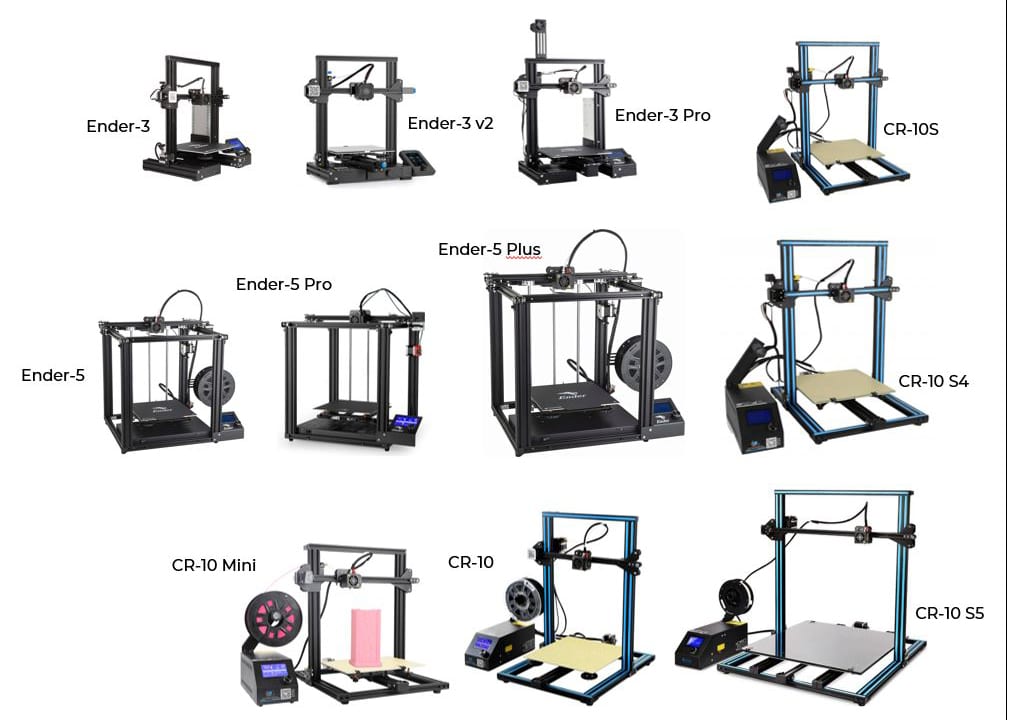

The following 3D printer models are compatible with Bondtech DDX v3 for Ender/CR-10(S):

Ender-3, Ender-3 v2, Ender-3 Pro, Ender-5, Ender-5 Pro, Ender-5 Plus, Ender-6, CR-10, CR-10 Mini, CR-10S, CR-10 S4, CR-10 S5, VoxelLab Aquila

Allows printing of abrasive and flexible materials in addition to basic filaments.

How to install a hotend Creality Ender/CR-10 on DDX v3 - This guide can also be used if you have a DDX v1 or DDX v2

With Bondtech DDX for CR-10(S)Pro/Max 3 models are compatible Creality:

CR-10S Pro, CR-10S Pro V2, CR-10 Max

Allows you to print flexible materials in addition to basic filaments.

How to install a hotend Creality CR-10(S) Max or Pro on DDX v3 - This guide can also be used if you have a DDX v1 or DDX v2.

PH2 > Phase 2

With a phase 2 upgrade you upgradehotend Creality with Copperhead™ Heat Break and Hot Block.

Main features of the phase 2 upgrade:

- No firmware upgrade is required

- Turn your hotend Creality into an all-metal hotend

- Allows you to print materials at higher temperatures (up to 260-270°C)

- You can reuse the stock components of your Creality: heat sink, thermistor, heating cartridge, fans.

How to install an hotend Ender/CR-10 updated PH2 on DDX v3 - DDX PH2 is based on Copperhead C-E Heat Break

How to install an updated hotend PH2 CR-10(S) Pro/Max on DDX v3 - DDX PH2 is based on Copperhead C-E Heat Break

PH3 > Phase 3

A phase 3 upgrade is a complete replacement ofhotend Creality with a Copperhead™ or Mosquito™ from Slice Engineering.

Main features of phase 3 upgrade:

- Required replacement ofhotend with Copperhead™, Mosquito™ or Mosquito™ Magnum

- Nozzle also needs to be upgraded: from the standard model Creality to a standard RepRap nozzle (M6x1x7.5×12.5)

- No firmware upgrade required

- Allows printing materials at higher temperatures (up to 260-270°C)

- You can reuse the standard components of your Creality: thermistor, heating cartridge, fans.

For nozzles being standard RepRap M6 many models can be used, including:

- Bondtech: standard Brass, standard Coated Brass, CHT Coated Brass (high flow).

- Slice Engineering: BridgeMaster (Copper), Vanadium Steel (for abrasive filaments)

How to install an update ofhotend PH3 Mosquito on DDX v3 - The same guide can be used with the Mosquito Magnum.

How to install an upgrade of thehotend PH3 Copperhead on DDX v3 - This hotend Copperhead uses the screw-in heatsink.

There are 2 more models compatible with DDX (PH1+PH3), in fact the DDX Direct Drive extruder Bondtech is compatible with Creality CR-10 v2 and CR-10 v3. In order to use it, it is necessary to:

- Bondtech DDX for 3D printers Creality

- DDX adapter set for CR-10 v2

- Upgrade hotend DDX PH3

PH4 > Phase 4

A phase 4 upgrade involves replacing the thermistor and heating cartridge with a 300°C thermistor and a 24V 50W heater.

Main features of the phase 4 upgrade:

- Firmware upgrade is required

- Original fans can be used Creality

- Only models with 24V power supply can be upgraded

- This upgrade allows you to increase the printing temperature up to 300°C*.

- By reaching high temperatures, engineering-grade thermoplastics such as PA6, PAHT CF, Iglidur C210-PF, Adura X Nylon, Iglidur J260-PF, FluorX Kynar PVDF, Koltron G1, and many others can be printed.

*The DDX allows you to increase the maximum nozzle temperature of compatible Creality 3D printers up to 300°C using these PHASE 4 upgrades, which provide a new thermistor, heater and firmware. Be careful, however, do not use nozzle temperatures above 300°C.

Pleasenote: Bondtech is not Creality. Minor inconsistencies have been highlighted in the production of Creality, so sometimes models may require different solutions than expected or minor adjustments. Please be aware and prepared.

The firmware can be updated with over 625 different setups

Full details for firmware update can be found here:

https://www.bondtech.se/knowledge-base/firmware-updates-for-creality3d/using-ddx/

A solution step by step according to your needs

The DDX therefore is a very versatile solution that makes improvements right from phase 1, and was created specifically for those who wish to transform Creality units from Bowden to Direct Drive.

The main philosophy of DDX includes 3 principles:

- minimalism

- versatility

- ease of installation and service

With DDX, as little as possible is added to the system and it is made very lightweight, while keeping user options open to future upgrades, thus also helping to make it easy to configure.

Given the variety of hardware choices in the Ender and CR families and the variety of user requirements and investment options, the 4-step solution allows for a gradual upgrade.

To recap:

Phase 1 > Using the originalhotend Creality

Phase 2 > Upgrade with block and Heat Break Copperhead™

Phase 3 > Full upgrade to hotend Copperhead™ or Mosquito

Phase 4 > Full upgrade to Copperhead™ or Mosquito™ with thermistor and heating cartridge change

Need technical support?

You can find guides on the Bondtech DDX extruder step-by-step by clicking here:

https://support.bondtech.se/c/DDX_for_Creality.html

If you need more information CONTACT US.

Follow our social media to stay up to date with the latest news!

CREDITS @Bondtech AB