Voron 2.4 STEP 5: Frame and linear guides of gantry (Core XY)

This fifth step for building your Voron 2.4 consists of the components for mounting the gantry, which represents a 4-point Z-leveling system and handles the X and Y axes via a core XY system.

So the main components are structural profiles, linear guides and pulleys.

This step will also need the blocks of A-drive / B-drive and A-idler / B-idler (pre-assembled in the previous step ). These are, in fact, 4 blocks to be mounted on the corners of gantry that will allow the movement of the x- and y-axes of the printer Voron 2.4.

What are the features of this STEP 5?

- Pulleys: this step of the Voron 2.4 kit includes the pulleys for transmitting motion. These are GT2 pulleys, which come in black anodized aluminum.

- Aluminum extruded profiles: anodized aluminum profiles cut to size and machined according to the official list Voron

- Nuts and fasteners: the nuts included in this step are spring-loaded 5-series aluminum profile nuts that can then be inserted into the slot as needed during construction without having to install them during pre-assembly.

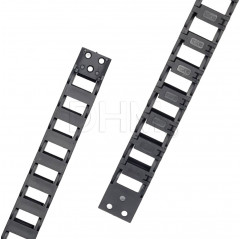

- MGN9 and MGN12 stainless steel linear guides from the DHM pro line: the hardened stainless steel linear guides will not rust and are extremely durable. (Guides are supplied individually packaged and lubricated ready for use. However, if assembly is prolonged over time, we recommend repeating the cleaning and lubrication procedure before commissioning.)

- Linear guide pads: arrive already assembled on the guides-these are medium preload pads to ensure high structural rigidity. When assembling the various parts, gantry will need to be turned upside down. We urge you, therefore, to clamp the runners on the rail-for example, by temporarily securing them with paper tape to make sure they do not stick out.

Note for assembly

- Important in this step pay attention to and check the squareness of the various parts of the gantry with each other and the assembly of the linear guides, which must be centered in the profiles. It is advisable to use the printed reference to align the guides to the profiles. You must also proceed with sequential assembly, according to the manual. Especially when going to install the X-axis in gantry.

- This step is crucial for the accuracy of the geometries of the prints you will later make with this 3D printer. We urge you, therefore, to pay attention to the details and when assembly is complete recheck that all components (pulleys, bearings, and guides) are aligned and adhere to the position indicated in the manual.

- We include in the kit brass grub screws for attaching the plastics. These threaded inserts have a special spiral profile to ensure the best possible seal. Manufactured from high-quality brass, they have excellent thermal conductivity and corrosion resistance.

- Plastics are not included by default but are optionally selectable. If they are selected all structural and aesthetic parts will be provided. Aiming for maximum quality, we have narrowed down the possible choices to two materials: Nylon Carbon and ASA. The former has excellent physical-mechanical properties, and the latter, a viable substitute for ABS, has optimized mechanical properties, UV resistance, and allows for extensive color customization. We have divided the printed parts into three groups: STRUCTURAL - PRIMARY - SECONDARY. Using these combinations you can get a unique specimen by choosing from more than 200 color combinations. Customization makes your Voron 2.4 personal and representative of your style!

Voron 2.4: an introduction

The Voron 2.4 is a motion 3D printer design CoreXY with a fixed top designed by Voron Design. This printer is known for its reliability and high performance.

Staying true to the fundamentals of the RepRap project, the Voron 2.4 is completely open-source, customizable and self-buildable.

The DHM kits of Voron 2.4 were born out of the need to gather the various requests of our customers: from those who struggle to find the material to those who have pointed out gaps and critical points in the kits already commercially available. The DHM kits are born from our experience in the 3D printing industry and knowledge of quality manufacturers. In addition, thanks to our in-house workshop, we have created custom components by making design improvements to give optimal reliability and performance.

The DHM kits from Voron 2.4 are currently available in 3 main variants that differ only in the size of the build space:

Kit Voron 2.4 250 mm → 250x250x250 mm

Kit Voron 2.4 300 mm → 300x300x300 mm

Kit Voron 2.4 350 mm → 350x350x350 mm

There is the possibility of some customization in some step of the kit, such as the choice of the extruder or the choice of the control board.

Do you want to build your own 3D printer Voron 2.4?

Our step-by-step kits for Voron 2.4 include 9 step + one optional tenth. In each step you will find the components for assembly accompanied by a manual with construction instructions and cautions.

We decided to divide the construction of Voron 2.4 into several steps to facilitate the assembly moments and also to allow for deferred purchase over time. We aim for quality and reliability of components rather than offering a cheap or incomplete kit.

Why buy a Voron 2.4 kit?

Owners of the Voron 2.4 praise it for its reliability and speed. Buying a kit printer allows you to customize various points: from the appearance, to the choice of size, type of electronics, extruder, and many others.

The Voron 2.4 DHM kit approach is to STEP: a step-by-step approach to building, each in his or her own time, a printer Voron. Each step has everything you need to finish that specific part of assembly, and this allows you to be able to pause the project and resume it without particular difficulty.

We have broken down and customized some of the steps in the official guide Voron into specific manuals for each step downloadable PDF. You will thus find step-by-step support for assembly. The manual for this step is available in the "Attachments" section of this page.

Keep an eye on our BLOG:

https://www.dhm-online.com/en/blog/printers-3d-voron-design-c13

The kit contains (BOM STEP 5 V2.4 350 mm):

1 x E Extrusion (2020 profiles) - 340mm

2 x C Extrusion (2020 profiles) - 450mm

1 x D Extrusion (2020 profiles) - 430mm

8 x Galvanized 5x10 round head screw with Allen recess

1 x Plastic centering guides mgn9 / mgn12 - PETG - Included

20 x Cylinder head screw with galvanized socket recess 3x8

8 x Cylinder head screw with galvanized socket recess 5x16

6 x Galvanized hex nut M5

8 x Cylinder-head screw with galvanized socket recess 5x40

8 x Steel shimming washer 5x10x1 mm

4 x Flanged bearing F695ZZ

10 x Cylinder head screw with galvanized socket recess 3x8

2 x Cylinder-head screw with galvanized socket recess 5x10

2 x Domed cylinder head screw with galvanized socket recess 5x16

2 x Domed cylinder head screw with galvanized socket recess 5x30

2 x Steel shim washer 5x10x1 mm

6 x Cylinder head screw with galvanized socket recess 3x16

3 x Brass threaded insert M3 - 3x4x5 mm (chain support)

26 x Nut with spring for post-assembly - Series 5 steel - M5 thread

34 x Nut with spring for post-assembly - Series 5 steel - M3 thread

2 x GT2 SINCRONA pulley Ø 5mm 20 teeth H6 - black in color

2 x MGN9 ball recirculating linear guideway 400 mm - 440C stainless steel

1 x MGN12 ball recirculating linear guideway 400 mm - Stainless steel 440C

OPTIONAL Plastic Kit XY joints

Check out related products for the next and previous STEP!