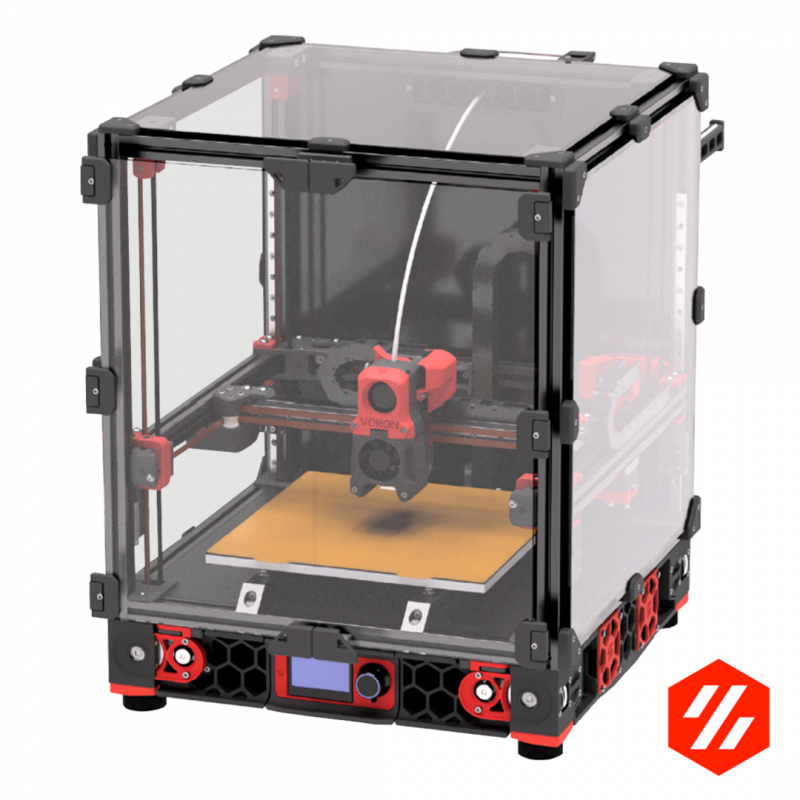

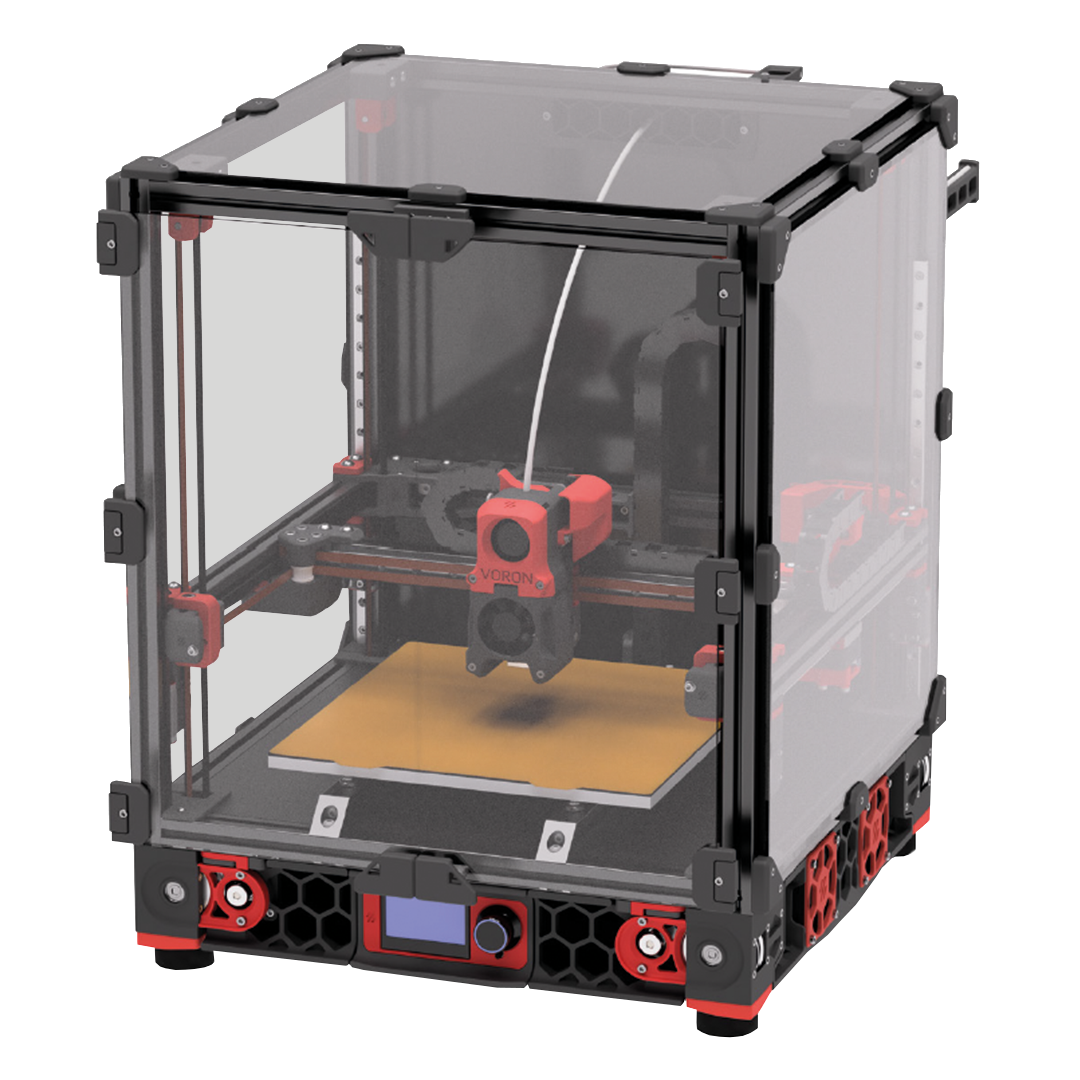

Voron 2.4 r2 made by DHM: the 3d kit printer for those who love performance and do not compromise.

With a long work of material selection and testing we propose the step by step version of the open-source project Voron 2.4, here grouped in a single bundle configurable at an unbeatable price.

The configurator is designed to allow the choice between various setups according to different needs and requirements. There are many possibilities for customization: from the basic self-build kit to the most complete kit with mounting options included.

The bundle for Voron 2.4 by DHM was born from our experience in the 3D printing industry, from our knowledge of high quality products, from having tested various models of Voron highlighting critical points in the kits already commercially available.

You can customize your Voron 2.4 r2 by choosing from top-of-the-line materials and accessories. From the choice of print volume (250mm, 300mm or 350mm model) to mechanical components, from the printing table to the extruder assembly and hot end, from electronics to finishes and plastic parts. Consider including additional services to achieve your ideal configuration; we'll take care of the rest!

Purchasing in the bundle mode provides a discount compared to buying individual components or individual step in bulk. You can purchase bundle with reservation by paying a deposit or with full payment in advance

At the end of the configuration you will find a summary with the total costs and the various purchase options with details on preparation and delivery times as well.

Why choose the kit DHM Voron 2.4 r2?

Union of performance and quality

Frame made of extruded aluminum profiles cut and machined directly in our workshop. MGN12 and MGN9 rails from DHM pro line extremely light and high performance.

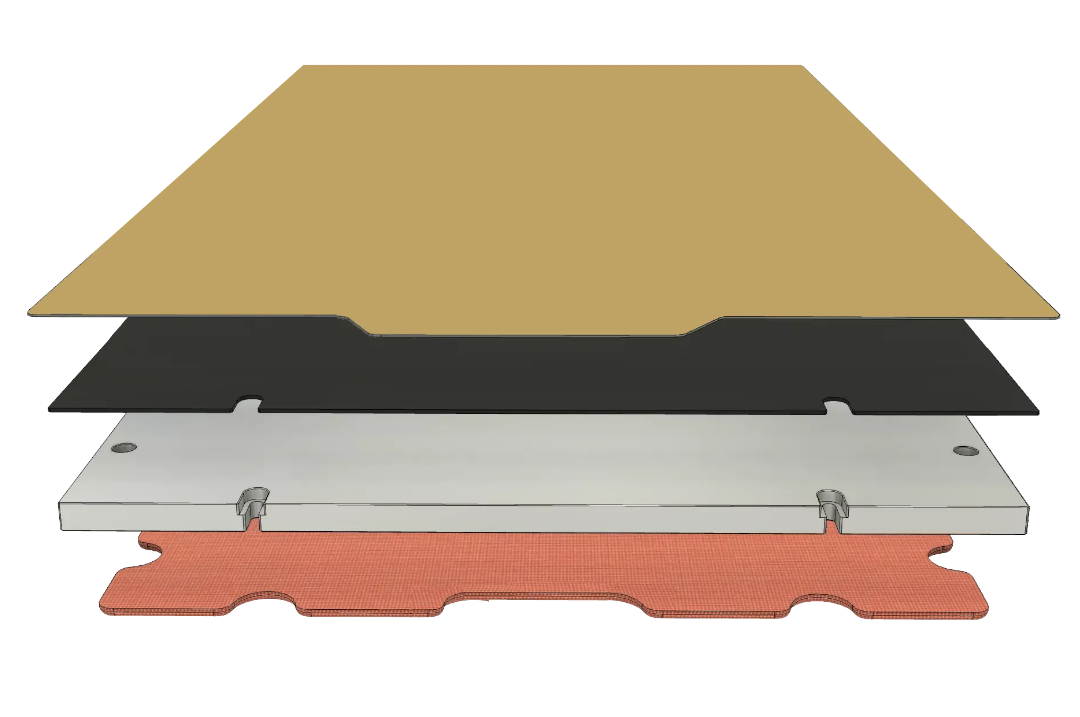

Customized performance

Ground and CNC machined from solid 5083 aluminum printing plate, Arlon silicone heating pad, magnetic base and PEI coated harmonic steel top. With these, the Voron 2.4 kit made by DHM can be adapted (depending on configuration) to print virtually any material on the market.

The perfect geometry of acceleration

Unique handling system with printing table fixed to the base of the machine and XY core system (gantry) that rises along z with 4-point self-calibration. This allows for a light and constant moving mass at all times to achieve the highest printing speeds along all axes without sacrificing accuracy.

Outstanding performance

The extruder assembly - Afterburner or Stealthburner - features the original Bondtech BMG push mechanism. Thehotend is selectable and you can opt from the best solutions currently available, including Revo voron (e3d), Mosquito Magnum (Slice Engineering) and Dragonfly BMO (Phaetus). Depending on the configuration chosen, therefore, many types of materials can be printed, including PLA, PETG, ABS, HIPS, PA (Nylon), PP, fillers and many others. Thanks to the direct extrusion mechanism, you can also work optimally with flexible-type 3D printer filaments such as TPC and TPU.

Simplification and wiring optimization

The electronics options included in bundle, both from Duet3D and Bigtreetech's, have been carefully selected with a view to simplifying machine wiring. For both, in fact, a CAN bus connection board is provided by default. As far as Duet3D is concerned, we are talking about the 1LC Toolboard, which makes it possible to reduce the cables for connecting the extruder assembly to just two, thanks precisely to the CAN-FD bus connection. Selecting BTT instead provides the EBB42 board for CAN bus connection.

The choice between the two types of boards is personal, but certainly our first choice falls on the components Duet3D, which provide maximum flexibility in machine design while maintaining high standards of reliability over time.

Starting with a solid base on the electronics side, the upgrade options are many. Some examples may be:

- creation of a print-farm with all printers on the network

- automatic systems for loading/unloading the print bed

- multi-extrusion system to facilitate multi-color printing, but also make thread change procedures automatic when running out for uninterrupted printing

Improved printing stability

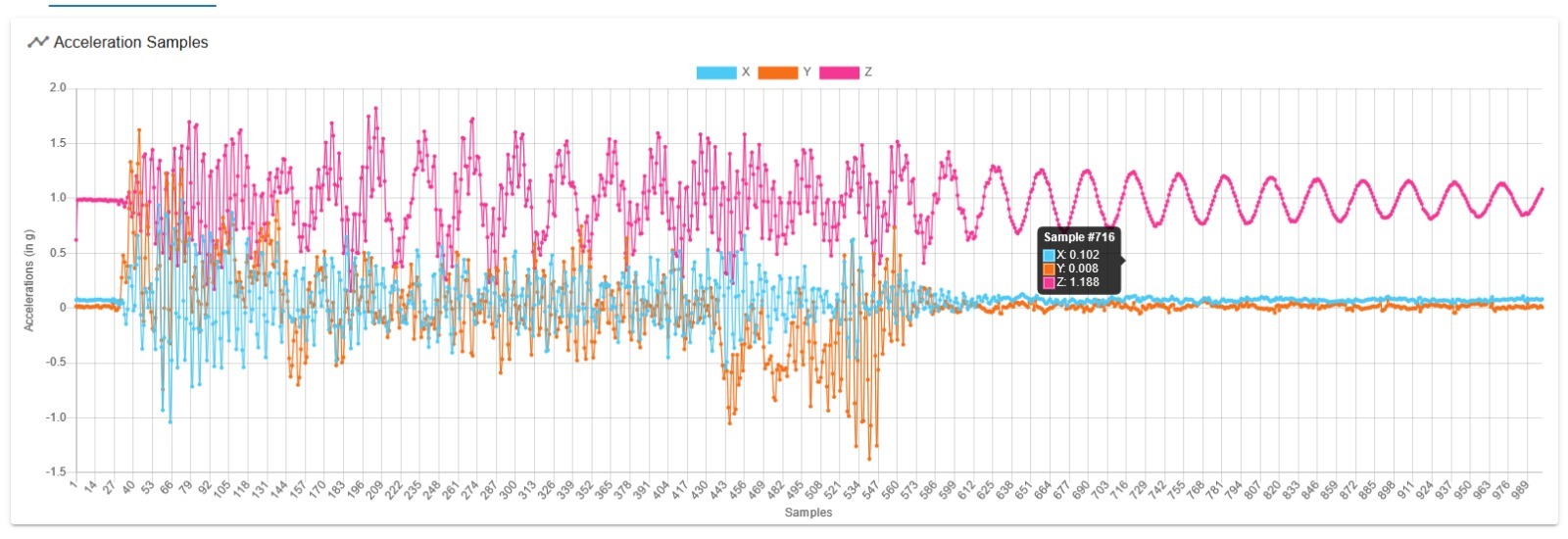

Using theaccelerometer built into the Duet3D 1LC board, motion analysis along the X- and Y-axes can be performed and automatic resonance compensation set up to minimize vibration, and increase the quality of printing surfaces. Using the Duet "Input Shaping" plugin you can do everything (from analysis to compensation settings) with the supplied electronics without additional expansion and wiring.

The BTT EBB42 CAN BUS board also has built-in ADXL345 accelerometer, which enables a number of advanced features to improve printer performance, depending on the firmware used.

Control and reliability

Smart control via Ethernet or wifi thanks to Duet3D 's original 32bit electronics and its native Duet Web control interface, or directly on board the machine using the screen.

In addition there is the possibility to install the filament sensor Duet3D for continuous control of the flow with prevention of possible printing errors due to: clogging of thehot end or extrusion system under stress (first layer too flattened, over-extrusions, exceeding volumetric flow rate hot end).

An alternative for Bigtreetech electronics is Smart Filament Sensor, a sensor that works with Marlin, Marlin2.0 and Klipper.

Performance and accuracy

Before starting the Voron 2.4 printer, the firmware must be loaded in order to print. With Duet electronics, you use RepRapFirmware, designed to take full advantage of the power of ARM processors to implement advanced features, kept up-to-date and stable directly by the team Duet3D.

In case, however, you choose Bigtreetech electronics, you can use Marlin or Klipper. In particular, Klipper is a firmware for 3D printers that starting from the instructions Gcode processes the machine's movements using the full power of the SBC's CPU. It handles multiple movements accurately, smoothly and efficiently. With the right parameters, it can maintain good print quality even at high speeds. Caution though. Klipper was not born as firmware for the inexperienced. In fact, it has endless configuration and customization options. Essential then to be able to use Klipper is to connect the motherboard to an SBC that controls it, such as Raspberry Pi4 or Banana Pi M5.

Note: Klipper can also work with RPI4-Duet3D system, but it is not recommended as the Duet system is already stable and performs well with RRF.

Attention to detail

The cables-with the possibility of pre-wiring-are high quality made in Italy. We have selected and sized them according to the task they perform in the printer and/or the location where they are installed.

For the wiring of the moving axes, it is possible to opt for two types of cable collectors: rigid pass-through chains on XYZ or a hybrid system with "umbilical" for the printhead and chains for YZ.

Using the CAN bus system reduces the cables to 5: two on motors A and B, one for XY limit switches mounted on the side of Gantry and two cables for expansion on the printhead. The "Umbilical" system minimizes and speeds up maintenance of the latter. It is the ideal configuration for users who need to make heavy use of the printer.

Cleaner air

Thanks to the HEPA filter and activated carbon filter, up to 95% of the particulate matter and emissions produced during printing are blocked for better and healthier air quality in the3D printer installation environment.

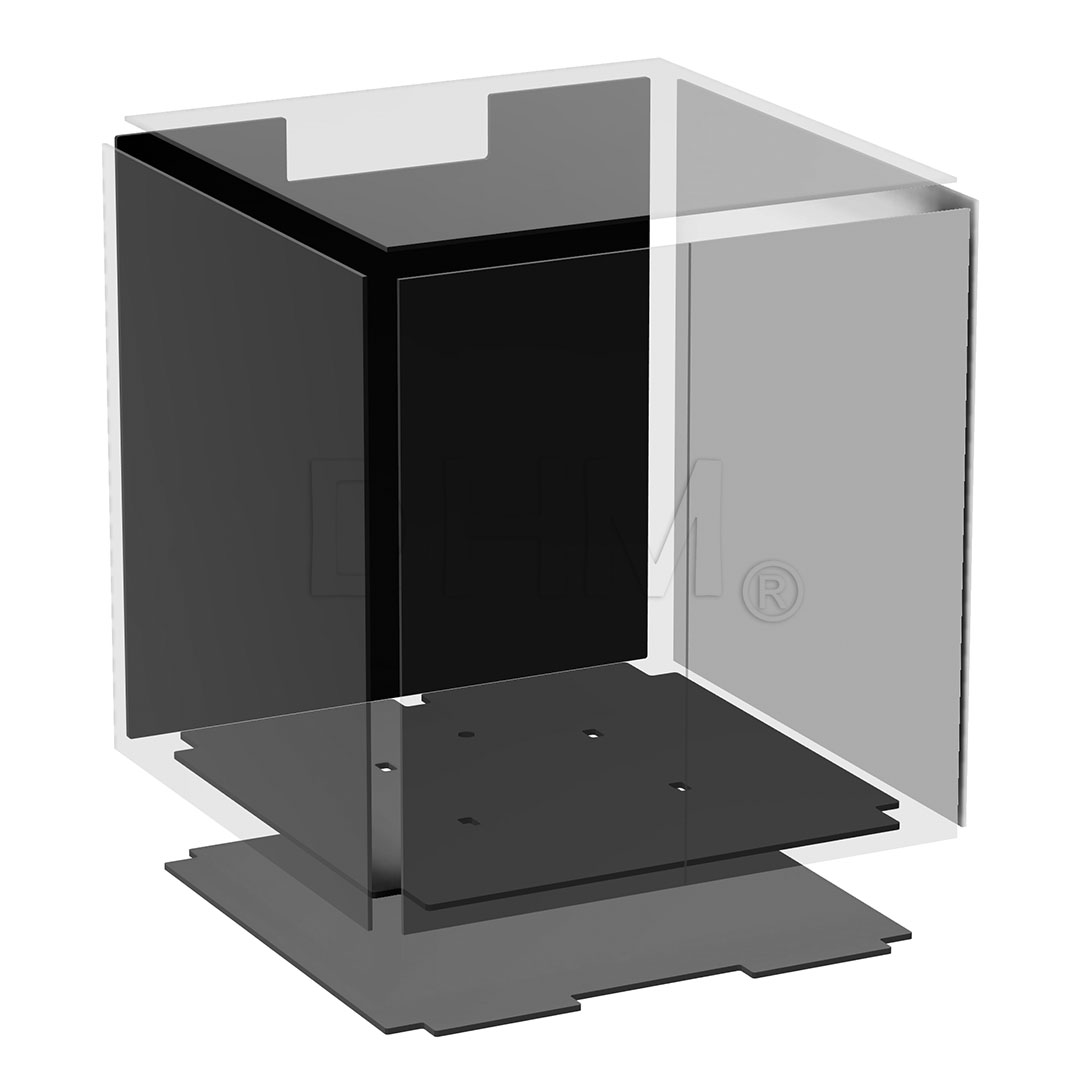

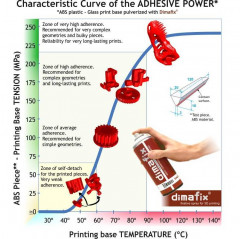

Printing technopolymers

Thanks to paneling and by choosing the appropriate components, technical filaments can also be printed. In fact, a passive hot chamber is created (made so by the color diffused from the print bed) that allows for excellent prints with ABS, ASA, Nylon and their respective fiber-filled fillers.

Make it unique

More than 200 aesthetic combinations to create the printer you want. Optional plastics printed with premium materials and in a wide range of colors, with the option of having the structural parts in Nylon Carbon, and the secondary parts in ASA.

A combination of features that enable performance and quality when printing for your Voron 2.4.

For assembly you can use the attachments of the individual step found at the bottom of the page. Also with the purchase of the kit will come an additional manual written by our team with tips and insights on assembly procedures.

For further details you can refer to the dedicated section of our blog:

https://www.dhm-online.com/en/blog/printers-3d-voron-design-c13

If there are any options that you would be interested in being added, or you have any doubt please contact us via the appropriate form.

The package contains:

The components of the kit that will be shipped are variable depending on the configuration you choose. Please refer to the individual step for a detailed list of components :