In the new E3D extruder ecosystem, the Revo family, there is a revamped structure.

Classic hot ends such as the E3D V6 can be thought of in two halves: a 'hot end' and a 'cold end'. These are separated by a 'HeatBreak', which does two things: mechanically unites and thermally separates the two halves.

Key features

- Integrated extruder and HotEnd

- A simple heatsink upgrade brings your existing Hemera into the Revo era

- Filament thrust up to 120N

- Faster heat-up times than the classic Hemera

Refurbished for the future

The Revo Hemera retains the design of the classic Hemera, but is compatible with the new Revo nozzles. The new heatsink has a longer hole for installing the Revo nozzles and a new space for attaching the Revo HeaterCore spring.

If you already own a Hemera you can upgrade! All you need is the Revo Hemera upgrade kit. Just replace the heatsink with a Revo compatible one, add a Revo HeaterCore and screw in your favourite Revo nozzle.

Flexible performance

The Hemera is the best choice for flexible filaments. The narrow path through which the filament passes prevents it from bending and deforming. The Revo configuration makes it easy to print advanced 3D printing materials and to adapt the nozzle to different printing requirements.

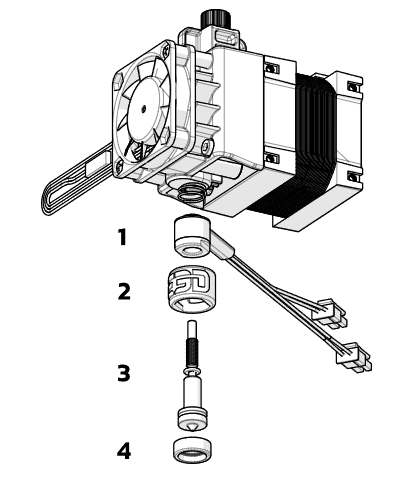

How to connect the HeaterCore to the Revo Hemera

Only 10 seconds to connect the hotend to the cold end of the Revo Hemera.

Last but not least!

The Revo Hemera can reach printing temperatures of up to 300°C:

- HeaterCore

- HeaterCore Sock

- Brass Revo Nozzle

- Revo Nozzle Sock

Discover the new Revo Hemera now!

Do you need technical support?

Consult the e3D guide: https://e3d-online.zendesk.com/hc/en-us/categories/4408227962513-Revo-Hemera

or CONTACT US

Follow our social networks to be always updated on the news!

CREDITS @E3D-Online