After a long year of product development and research into 3DSolex core heating technology, Bondtech has introduced the high-flow CHT® nozzles.

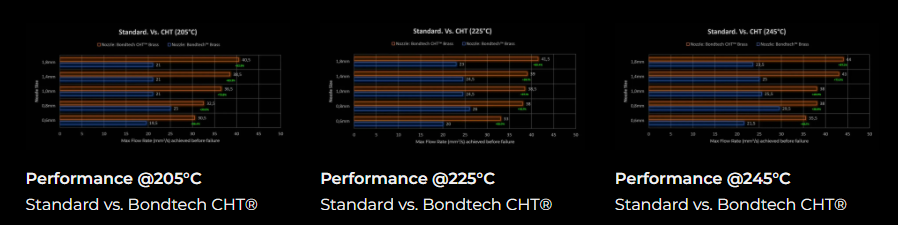

These new CHT® nozzles bring an average gain in volumetric flow performance of more than 60%, as demonstrated by the study carried out by Bondtech (white paper).

A challenge at 26mm^3/s

The video below shows a challenge between two 0.6mm nozzles running on a Prusa MK3S with an LGX® Shortcut Copperhead™ Upgrade Kit and a Bondtech® 50W heater. Left is a standard coated brass nozzle. Right is a Bondtech CHT® nozzle.

One model is sliced to pass through a slow increase in speed and flow rate from 17 up to 26 mm^3/s. The same G-code is used on both jobs.

Both nozzles work well up to 19 mm^3/s. Above that, performance differences are clearly visible. Which of the two will do a better job?

Main advantages of Bondtech CHT® nozzles

- Higher melting capacity due to increased surface area of the heating walls

- Affordable price

- Machined with ultra-precision

- Brass nozzle with nickel-coated surface

- Follows nozzle standards: RepRap (M6×1×7.5×12.5) - MK8 (M6×1×5×13)

- Can be used with 1.75 or 2.85mm hotends

Bondtech CHT® nozzles split the filament into 3 thinner filaments allowing the material to be melted from the inside. By doing so, the material melts faster and higher flow rates can be used.

Core Heating is a patented technology

Registration number: EP3445568A1

Nozzles for metal 3D printers with at least one or a multitude of holes to increase the surface area of the heating walls.

Advantages of nickel coating

CHT nozzles are made of nickel-coated brass. This provides protection against corrosion, erosion and abrasion.

These nozzles have a higher resistance to corrosion and a lower coefficient of friction, which allows a smoother material feed and delays the adhesion of plastic to the nozzle surface.

Recommended materials

Use this nozzle with the following materials

- PLA

- ABS

- HIPS

- PC

- TPU

- TPE

- Nylon

- PETG

- ASA

- PP

- PVA

CHT nozzles are currently not recommended for use with technical and abrasive materials. A version suitable for this type of material is under development.

Discover the whole range here: https://www.dhm-online.com/505-ugelli-nozzles

Need technical support?

See the white paper: https://www.bondtech.se/intranet/white-paper-max-flow-rate/

If you need more information CONTACT US

Follow our social media to keep up to date with the latest news!

CREDITS @Bondtech AB